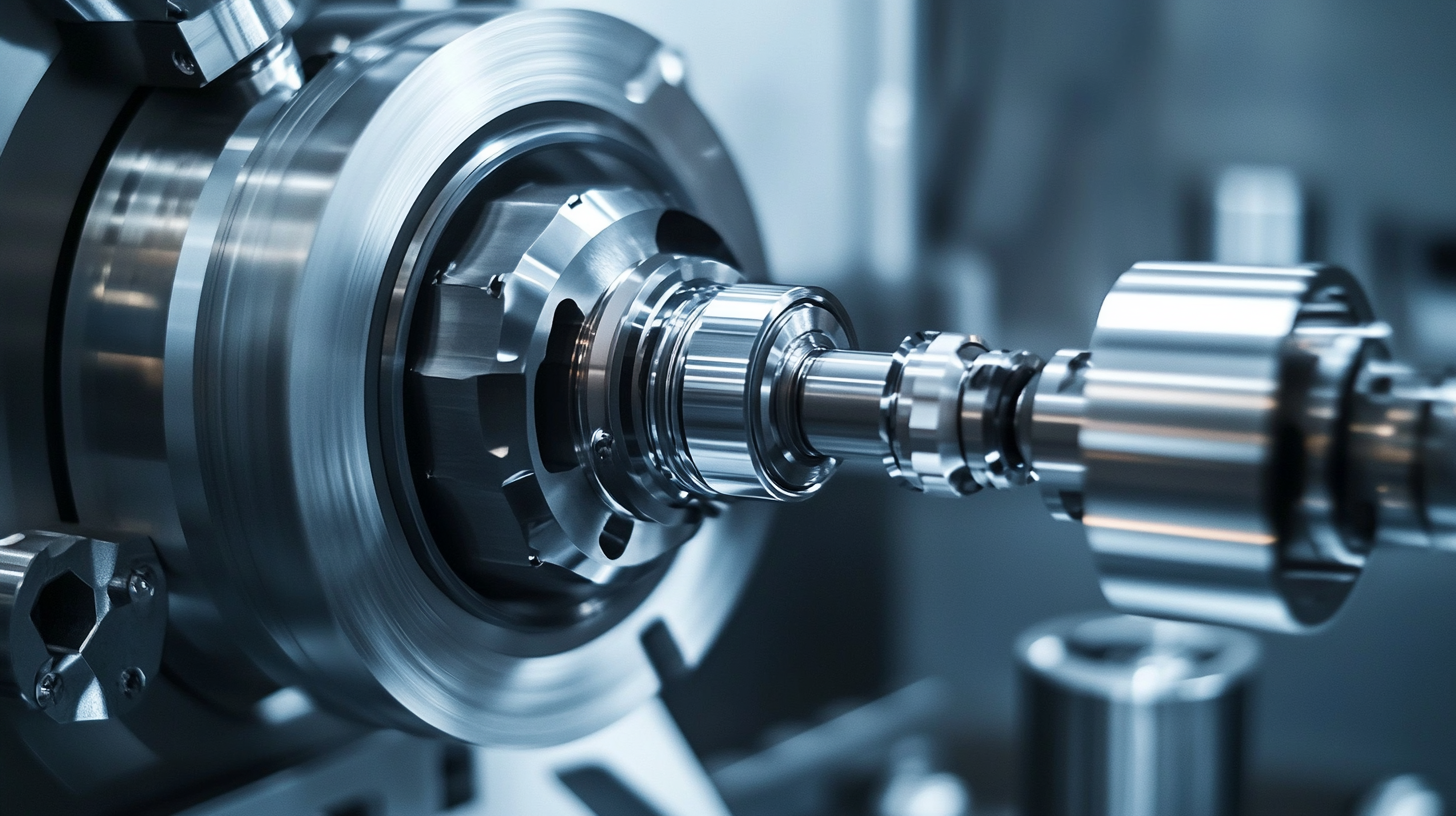

In the rapidly evolving landscape of manufacturing technology, the demand for high-performance tools is more critical than ever. Among these tools, PCD turning inserts have emerged as a game changer in the global procurement sector, offering exceptional durability and precision for a variety of machining applications. As we look ahead to the technological developments expected by 2025, it is imperative to explore the advantages of utilizing the best PCD turning inserts in production processes. This blog will delve into the myriad benefits of these cutting-edge inserts, emphasizing how they can enhance efficiency, reduce costs, and ultimately lead to superior product quality. By unlocking the potential of PCD turning inserts, manufacturers can not only keep pace with industry advancements but also gain a competitive edge in the global market.

In the rapidly evolving landscape of manufacturing technology, the demand for high-performance tools is more critical than ever. Among these tools, PCD turning inserts have emerged as a game changer in the global procurement sector, offering exceptional durability and precision for a variety of machining applications. As we look ahead to the technological developments expected by 2025, it is imperative to explore the advantages of utilizing the best PCD turning inserts in production processes. This blog will delve into the myriad benefits of these cutting-edge inserts, emphasizing how they can enhance efficiency, reduce costs, and ultimately lead to superior product quality. By unlocking the potential of PCD turning inserts, manufacturers can not only keep pace with industry advancements but also gain a competitive edge in the global market.

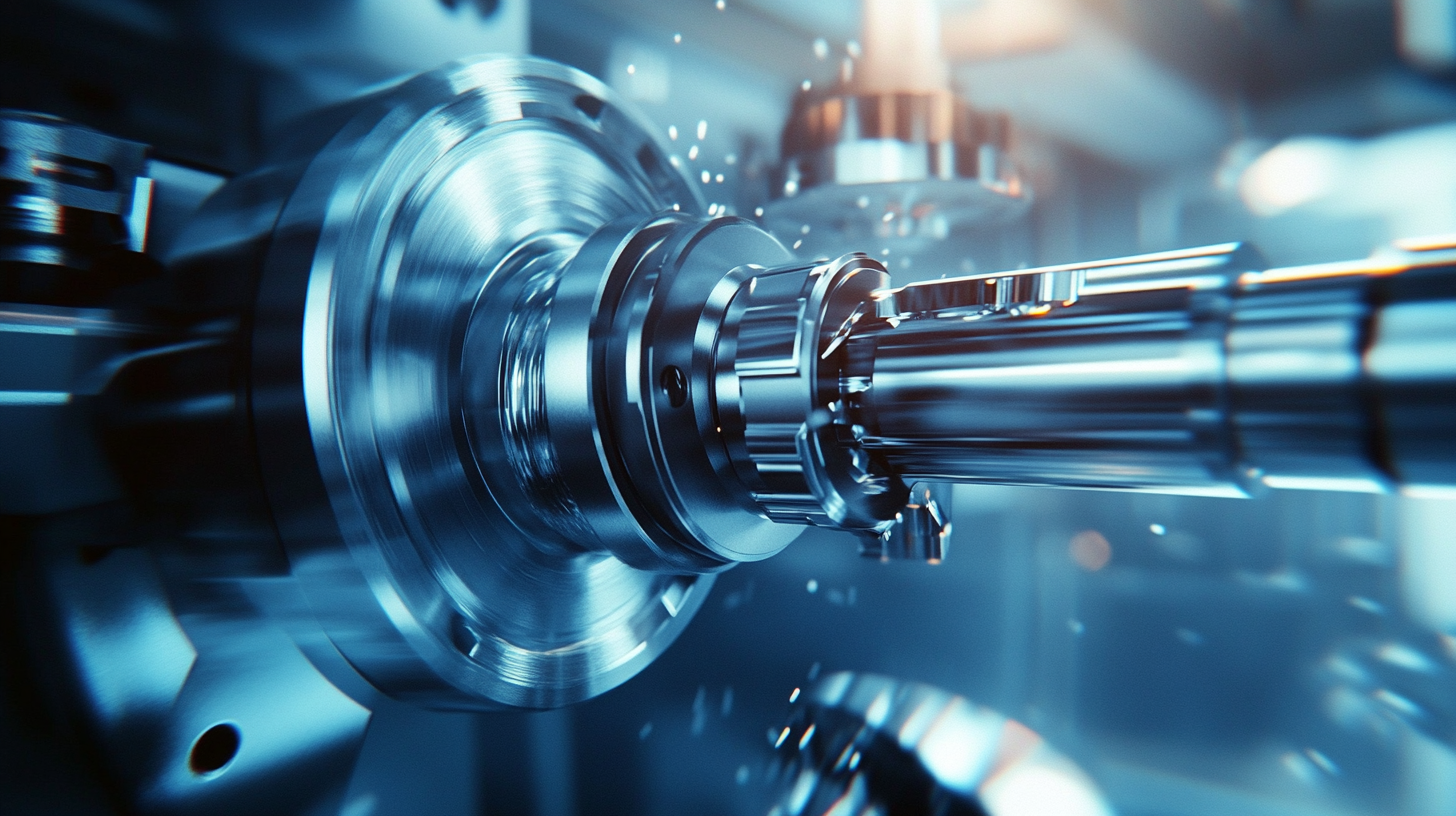

As we look toward 2025, the emergence of new technologies in PCD (polycrystalline diamond) turning inserts is set to revolutionize the machining industry. These advanced inserts provide exceptional durability and thermal resistance, dramatically enhancing efficiency and performance in various manufacturing processes. Innovations, such as advanced coating techniques and improved diamond grain structures, are aimed at reducing tool wear and optimizing cutting conditions. Manufacturers adopting these technologies can expect not only to boost production speed but also to improve overall cost-effectiveness.

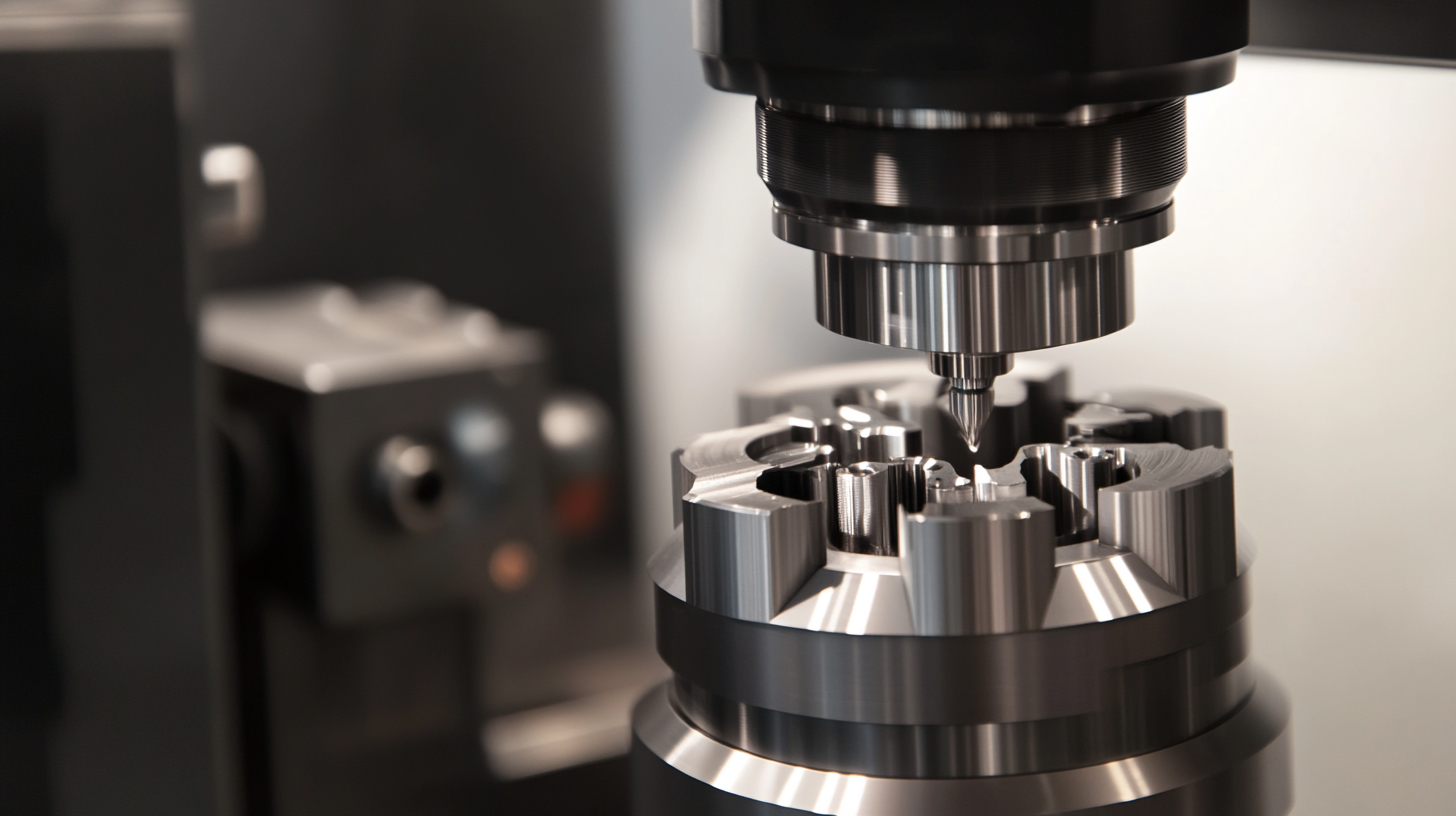

Tip: To maximize the benefits of PCD turning inserts, ensure that you select the right geometry for your specific application. Different shapes and sizes can significantly influence cutting performance and tool life.

Furthermore, the integration of smart technology, like IoT-enabled monitoring systems, will facilitate real-time analysis of tool performance. This proactive approach allows for timely replacements and adjustments, reducing downtime and maintaining productivity. As the adoption of these intelligent systems increases, manufacturers will be better positioned to respond swiftly to changing production demands and enhance their competitive edge.

Tip: Regularly review and adjust your machining parameters based on tracking data to ensure optimal efficiency from your PCD inserts. Adapting to performance insights can significantly extend tool lifespan and improve output quality.

The global market for PCD (Polycrystalline Diamond) cutting tools is expected to witness significant growth in the coming years. This surge can be attributed to the increasing demand for high precision machining in various industries, including automotive, aerospace, and electronics. As more manufacturers seek to optimize their production processes, the adoption of advanced cutting tools, particularly PCD turning inserts, becomes essential. These tools not only enhance machining efficiency but also offer longer tool life and improved surface quality, ultimately driving down operational costs.

When considering procurement strategies for PCD cutting tools, it’s essential to conduct thorough market research. Understanding the various suppliers and the quality of their offerings can greatly impact your production capabilities. Tip: Always compare the specifications of different turning inserts and their applications to ensure that you select the most suitable options for your specific machining needs.

Additionally, maintaining a good relationship with suppliers can lead to better procurement deals and access to innovative products. Emphasizing collaboration and communication can help both parties align on quality expectations and industry trends. Tip: Regularly revisit your procurement strategy and adapt to market changes to stay ahead in the competitive landscape of manufacturing.

| Region | Market Size (USD Billion) | Projected Growth Rate (%) | Key Applications | Challenges |

|---|---|---|---|---|

| North America | 2.5 | 5.2 | Aerospace, Automotive | High costs, Supply chain issues |

| Europe | 3.0 | 4.7 | Machinery, Electronics | Regulatory compliance, Aging workforce |

| Asia-Pacific | 4.0 | 6.5 | Automotive, Electronics | Infrastructure challenges, Technology adaptation |

| Latin America | 1.2 | 3.8 | Mining, Oil & Gas | Economic instability, Limited technology access |

| Middle East & Africa | 1.0 | 4.0 | Oil & Gas, Construction | Political instability, Resource depletion |

The global manufacturing landscape is witnessing a

paradigm shift

driven by innovative advancements in

Polycrystalline Diamond (PCD) insert

design. PCD inserts offer unparalleled wear resistance and longevity,

resulting in significantly reduced tool replacement costs.

According to a recent report by

MarketsandMarkets, the demand for

advanced cutting tools, including PCD inserts, is expected to grow at a

CAGR of around 6%

between 2021 and 2026, indicating a robust trend towards high-performance

materials in machining operations.

The global manufacturing landscape is witnessing a

paradigm shift

driven by innovative advancements in

Polycrystalline Diamond (PCD) insert

design. PCD inserts offer unparalleled wear resistance and longevity,

resulting in significantly reduced tool replacement costs.

According to a recent report by

MarketsandMarkets, the demand for

advanced cutting tools, including PCD inserts, is expected to grow at a

CAGR of around 6%

between 2021 and 2026, indicating a robust trend towards high-performance

materials in machining operations.

Key innovations include the development of multi-layered PCD coatings

and tailored geometries that enhance chip removal and thermal conductivity.

For instance, a study conducted by the

International Journal of Machine Tools and Manufacture

highlighted that PCD inserts with optimized geometries can improve machining

efficiency by up to

30%. These design

advancements not only boost operational productivity but also allow

manufacturers to tackle complex materials like composites and hardened steels,

which are increasingly prevalent in industries such as

aerospace and

automotive.

Moreover, the integration of smart manufacturing technologies with PCD

inserts is enabling more precise machining processes. The ability to

monitor tool wear in real-time through

IoT-enabled systems

enhances predictive maintenance, ultimately reducing downtime and manufacturing

costs. As companies leverage these cutting-edge innovations, demonstrating

a commitment to

efficiency and sustainability

will be essential for maintaining a competitive edge in the evolving global market.

As we move towards 2025, sustainability is becoming increasingly pivotal in the manufacturing of polycrystalline diamond (PCD) tools. The industry is witnessing a significant shift towards greener practices, with manufacturers focusing on reducing their carbon footprint and minimizing waste. Innovations in recycling techniques are enabling the recovery of valuable materials from worn-out PCD inserts, ensuring that resources are used more efficiently. This not only cuts costs for producers but also promotes a circular economy that stands in stark contrast to traditional, linear manufacturing processes.

Moreover, the integration of sustainable materials and energy-efficient manufacturing techniques is reshaping the PCD landscape. Companies are now exploring alternatives to conventional coolants and are investing in renewable energy sources to power their operations. These efforts are essential, not only for compliance with international regulations but also for meeting the growing demand from consumers and businesses for environmentally responsible products. With the focus on sustainability, PCD manufacturers can not only enhance their market appeal but also play a crucial role in the global transition towards a more sustainable future.

The global market for high-performance PCD turning inserts continues to expand as manufacturers seek cost-effective solutions that enhance productivity. These inserts exhibit exceptional hardness and wear resistance, driving down operational costs and increasing machining efficiency. The recent advancements in diamond-enhanced shear-cutting elements, specifically within the oil and gas drilling industry, exemplify how materials are evolving to meet the rigorous demands of modern manufacturing. By integrating PCD technology, companies can achieve superior cutting performance while minimizing downtime and maximizing output.

Tips for optimizing your use of PCD turning inserts include selecting the right grade of insert for your specific application. Understanding the material being machined is crucial; for instance, softer materials may require different inserts than harder alloys. Additionally, maintaining proper cutting parameters—such as speed, feed rate, and depth of cut—can lead to significant improvements in tool life and part quality.

Investing in high-performance PCD turning inserts can yield considerable economic benefits when aligned with strategic procurement practices. As the carbide insert market thrives, integrating innovative materials like PCD can set manufacturers apart in a competitive landscape, ensuring they meet both quality and cost targets efficiently.