In today's fast-paced world, the selection of the right cutter tool can significantly impact both the efficiency and quality of your work. Whether you're a professional tradesperson or a DIY enthusiast, understanding the various types of cutter tools available is crucial to achieving optimal performance. However, with a myriad of options on the market, choosing the best cutter tool may seem overwhelming.

This blog aims to unveil a comprehensive comparison of the top cutter tools, highlighting their strengths and weaknesses while addressing common problems associated with each type. By examining the features, materials, and functionalities that define these tools, readers will gain valuable insights to make informed decisions. Join us as we delve into the intricacies of cutter tools to empower your next project with the precision and reliability you deserve.

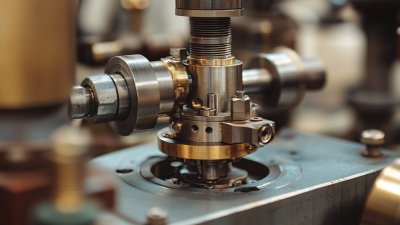

When it comes to achieving optimal performance in various industrial applications, understanding the different types of cutter tools is essential. Cutter tools, ranging from traditional twist drills to advanced carbide inserts, play a crucial role in manufacturing efficiency. According to a recent report by Grand View Research, the global cutting tools market is expected to reach $35.89 billion by 2025, driven by the rising demand for precision engineering and automation. This highlights the increasing importance of selecting the right cutter tools for specific tasks.

Choosing the appropriate cutter tool can significantly enhance performance and productivity. For instance, High-Speed Steel (HSS) tools are ideal for low-speed operations, while carbide tools excel in high-speed applications due to their hardness and heat resistance. A study from the Manufacturing Technology Association suggested that using specialized tools tailored to the material being cut can improve cutting speed by up to 30%.

**Tip:** Always consider the material of both the cutter and the workpiece. For softer materials, opt for tools with a sharper edge to ensure clean cuts, while harder materials may benefit from tougher, more durable cutter tools.

Additionally, regular maintenance of your cutter tools can prolong their lifespan and maintain cutting efficiency. According to the Tooling and Manufacturing Association, routine inspections and cleaning can reduce tool wear by 25%, allowing for consistent performance and superior results.

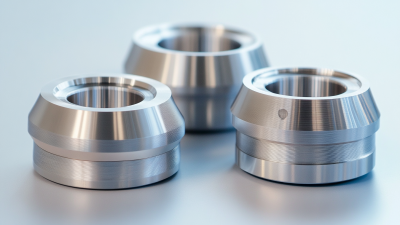

When selecting a high-quality cutter tool, understanding its key features is essential for optimal performance. First and foremost, consider the material of the cutter. Tools made from high-speed steel or carbide offer durability and resistance to wear, making them ideal for various cutting tasks. Additionally, the cutter's design plays a significant role; ergonomic shapes ensure comfort during extended use, reducing fatigue and improving precision.

Another critical feature to look for is the tool's cutting edge. A finely honed edge enhances cutting efficiency, while advanced coatings can reduce friction and prolong the tool's lifespan. It’s also important to evaluate the tool’s compatibility with different materials, whether primarily working with metals, plastics, or composites. Understanding these aspects can greatly influence the effectiveness of your cutting projects.

**Tips:** Always check for product reviews and ratings to gauge performance from other users. Investing in a tool with a solid warranty can also safeguard your purchase. Finally, don’t hesitate to consult with experts or manufacturers to ensure you select a cutter tool that meets your specific needs for optimal results.

When it comes to selecting the best cutter tools for your projects, understanding the differences and advantages of each option on the market is crucial. Our comparative analysis dives deep into the leading cutter tools, highlighting their features, performance, and usability. From utility knives to precision cutters, we examine factors such as blade material, ergonomics, and cutting capacity that influence a tool's effectiveness tailored to specific tasks.

One standout in our analysis is the premium utility knife, known for its durability and ease of blade replacement. It excels in a variety of cutting scenarios, providing a comfortable grip that minimizes user fatigue. Conversely, precision cutters target detailed work and intricate designs, featuring razor-sharp blades that deliver clean cuts with minimal effort. By comparing these instruments side by side, we reveal the strengths and weaknesses of each tool, enabling users to make informed choices based on their individual needs and preferences in the ever-evolving landscape of cutting tools.

| Tool Type | Material | Weight (lbs) | Blade Length (inches) | Usage Type | Price ($) | Rating (out of 5) |

|---|---|---|---|---|---|---|

| Utility Knife | Steel | 0.8 | 4 | General | 12.99 | 4.5 |

| Box Cutter | Plastic/Metal | 0.5 | 3 | Light Duty | 9.99 | 4.2 |

| Craft Knife | High Carbon Steel | 0.4 | 3.5 | Art/Crafts | 15.49 | 4.7 |

| Shear Cutter | Stainless Steel | 1.2 | 6 | Heavy Duty | 24.99 | 4.8 |

| Electric Cutter | Metal | 3.5 | 5 | Industrial | 99.99 | 4.9 |

When it comes to maximizing the efficiency and longevity of cutter tools, adopting best practices is essential. First and foremost, regular maintenance is vital. This includes cleaning the tools after each use to prevent build-up of materials that can impair performance. Using appropriate lubricants not only reduces friction but also protects the blades and cutting edges from wear. Additionally, keeping cutting tools sharp is crucial; dull blades can lead to increased effort and reduced precision, ultimately compromising the quality of your work.

Proper usage techniques should also be emphasized. Understanding the specific capabilities and limitations of each tool ensures optimal performance. For instance, using the right cutter for the material at hand—be it wood, metal, or plastic—can significantly affect outcomes. Moreover, employing the correct technique can prevent accidents and extend the tool's lifespan. Always follow safety guidelines and use protective gear to safeguard against any mishaps during the cutting process. By adhering to these best practices, users will not only enhance their cutting efficiency but also enjoy a safer and more productive working environment.

When it comes to selecting the right cutter tool for your needs, there are several key factors to consider. First and foremost, it's essential to identify the material you'll be working with. Different cutting tasks require different tools; for instance, a utility knife is perfect for cardboard and soft materials, while a jigsaw is better suited for wood or metal. Understanding the specific requirements of your project will help narrow down your options and ensure you choose the most effective cutter.

Another crucial aspect is the design and ergonomics of the cutter tool. A well-designed tool can greatly enhance your performance and comfort during use. Look for features such as rubber grips, lightweight materials, and an intuitive design that makes handling and maneuvering easy. Additionally, consider the maintenance and durability of the tool – investing in a high-quality cutter can lead to long-term savings and performance reliability. By taking these expert tips into account, you can confidently select a cutter tool that not only meets your immediate needs but also enhances your overall efficiency and effectiveness in your tasks.