The landscape of manufacturing continues to evolve, driven by technological advancements. The Injection Molding Machine With Robot integration stands out as a pivotal innovation. According to the International Plastics Arbitration Council, the demand for these machines is expected to grow at a rate of 8% annually through 2026. This trend is reshaping the industry, encouraging companies to adopt automation solutions for efficiency and precision.

Renowned industry expert Dr. David Liu notes, "Maximizing the benefits of robotics in injection molding can significantly enhance productivity." His insights highlight the importance of merging robotics with injection molding technology. However, challenges remain. Many companies grapple with the initial costs and the complexity of implementation. Achieving operational synergy between machines and robots can be daunting.

Despite this, the potential rewards are substantial. Enhanced cycle times and reduced labor costs drive many manufacturers to explore Injection Molding Machine With Robot options. As the industry moves forward, adaptation and continuous learning will be key. The future holds exciting opportunities, but reflection and strategic planning will be essential to navigate the intricacies of this transformation.

In 2026, injection molding machines are evolving rapidly. The global market for these machines is projected to reach $15 billion by 2026. This growth highlights the increasing demand for efficiency and precision in manufacturing. Many companies are adopting advanced robotics to enhance production processes.

The integration of robots in injection molding improves operational efficiency. Reportedly, production times can be reduced by up to 30% with automation. This reduction leads to lower labor costs and increased output. Robots can also handle complex tasks, which simplifies operations for manufacturers. However, not every facility is ready to embrace these technologies. Transitioning can require significant investment and training.

Challenges still exist. Some manufacturers face difficulties in integrating robotics with existing machinery. Compatibility issues may arise. Moreover, smaller companies often struggle to afford the latest machines with robotic features. This divide could impact their competitiveness. Understanding these trends and obstacles is essential for staying ahead in the injection molding industry.

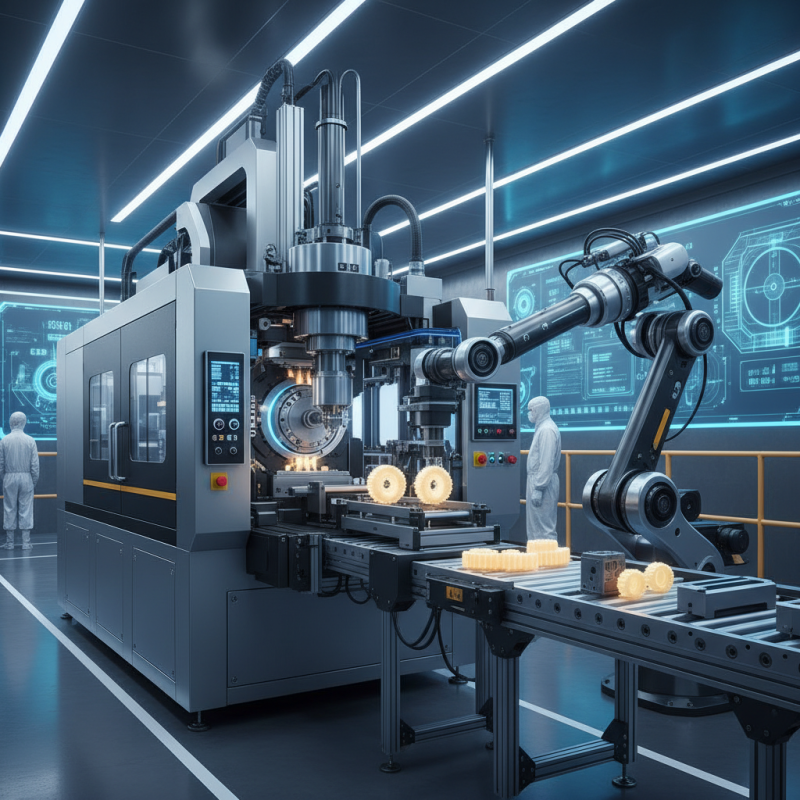

Modern injection molding machines are revolutionizing manufacturing with advanced features. These machines now often come with integrated robotics, enhancing efficiency and precision. According to a recent industry report, companies utilizing robotic systems in their injection molding processes can see production rates increase by up to 30%. This boost comes from the robots' ability to automate part handling and assembly, reducing human error.

Additionally, energy efficiency has become a key focus. The latest data indicates that modern machines consume 20% less energy compared to those manufactured a decade ago. This shift not only lowers operational costs but also aligns with global sustainability goals. However, many manufacturers still struggle with the integration of these technologies. There is a learning curve that can slow down initial production rates.

Moreover, advanced monitoring systems are now standard. These systems provide real-time data, helping operators make informed decisions. Nonetheless, the reliance on technology poses a challenge. Technical issues can lead to downtime, impacting overall productivity. The balance between technology and human oversight remains a crucial topic for consideration.

The integration of robotics into injection molding processes is reshaping the industry. Robots can handle tasks like loading, unloading, and assembly, which enhances efficiency. These machines work seamlessly with injection molding systems. The synergy between robots and molding machines leads to faster production cycles.

However, challenges remain in adoption. Many manufacturers hesitate because of the initial costs. Training staff to operate new robotic systems is another hurdle. Not all operators feel comfortable with advanced technology. This gap can slow down the transition to more automated systems.

Despite these issues, the benefits are clear. Robots reduce labor costs over time and improve precision in the molding process. They can also operate in hazardous environments, keeping human workers safe. Companies will need to weigh these advantages against the challenges. Adapting to robotic integration is a journey with ups and downs.

Automated injection molding with robotics is transforming the manufacturing sector. This integration delivers enhanced precision and efficiency. According to a recent market report, over 40% of injection molding operations now utilize robotics. This trend is driven by the demand for lower costs and higher productivity.

Robots streamline tasks like part removal and material handling. They significantly reduce cycle times, often by 20-30%. This efficiency means manufacturers can produce more with less downtime. However, the initial investment in robotic systems can be high. Some companies hesitate, unsure of long-term gains.

Quality control is another critical benefit. Robotics ensures consistent production quality, reducing errors. The American Society for Quality states that automation can lower defect rates by as much as 50%. Nonetheless, relying entirely on machines can lead to skill gaps among staff. Training becomes vital to maintain a skilled workforce in an automated environment.

The future of injection molding machines is evolving rapidly. Automation is driving significant changes. Robots are becoming essential in production lines. They enhance speed and precision. Their integration reduces labor costs and improves efficiency.

New trends introduce advanced sensors. These sensors monitor the injection process in real-time. Such technology helps in detecting defects early. Quality control becomes more effective with these measures. The machines are getting smarter and more intuitive. However, the complexity of programming these systems is a challenge. Not all operators are skilled enough to manage them.

Moreover, sustainability is on the horizon. Machines are being designed to use less energy. However, manufacturers often struggle with balancing efficiency and cost. Recycling is becoming important too. Effectively integrating recyclable materials in production can be tricky. There's a learning curve in adapting to these new methods. The future is exciting, but it demands continuous improvement and adaptation.