In the world of machining, selecting the right tools is crucial for achieving optimal results, and among these tools, the milling cutter stands out as an essential component for various applications. Whether you are engaged in precision engineering or mass production, understanding the different types of milling cutters and their specific uses can significantly impact your project's efficiency and quality. This blog aims to unveil the best milling cutter options available in the market, tailored to meet diverse machining needs. From face mills to end mills, we will explore the features, advantages, and suitability of each cutter type, equipping you with the knowledge to make informed decisions. Join us on this journey as we dissect the key attributes of milling cutters that enhance productivity and ensure superior machining outcomes.

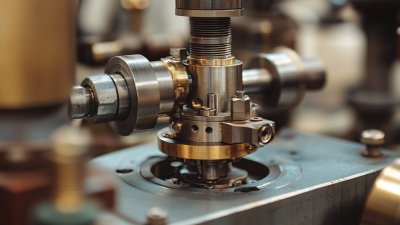

Milling cutters are essential tools in the machining process, designed to remove material from a workpiece with precision and efficiency. Understanding the different types of milling cutters available is crucial for selecting the right tool for specific tasks. Common types include end mills, face mills, and slab mills, each serving unique functions in milling operations. End mills, characterized by their cutting on both the end and periphery, are ideal for complex shapes and contours, making them versatile for various projects.

Face mills, on the other hand, are used primarily for large surface areas, providing a flat finish. They are mounted on the spindle and operate perpendicular to the workpiece, making them effective for removing bulk material quickly. Slab mills, known for their large diameter, excel in heavy stock removal and are often employed for machining flat surfaces. By understanding these milling cutter types and their specific applications, machinists can enhance their workflow and achieve better results in their machining endeavors.

High-Speed Steel (HSS) milling cutters have become a cornerstone of modern machining, offering significant advantages in terms of efficiency and versatility. Composed primarily of tungsten, molybdenum, chromium, and vanadium, HSS is a high-carbon alloy tool steel designed to withstand the rigors of high-speed operations while maintaining exceptional hardness and durability. According to a recent industry report, the global demand for HSS tools is projected to grow at a CAGR of 5.4%, driven by advancements in manufacturing processes and increasing automation.

One of the key benefits of HSS milling cutters is their ability to retain sharpness even under high temperatures, which is crucial for precision machining. They can operate effectively at cutting speeds of up to 80 m/min, making them suitable for a wide range of applications, including complex die machining and high-volume production runs. Furthermore, HSS tools are known for their cost-effectiveness; while they may have a higher initial investment compared to carbide tools, their longevity and performance can lead to lower overall operational costs. As the machining industry evolves, the demand for reliable and high-performance HSS milling cutters will undoubtedly continue to rise, ensuring their place as essential components in advanced manufacturing environments.

In the ever-evolving landscape of machining, carbide milling cutters stand out due to their exceptional durability and precision. These tools leverage the robust properties of tungsten carbide, a material set to dominate the market as demand surges in sectors such as automotive and aerospace. The milling cutter's design is critical; advancements in tool coating technologies enhance both tool life and performance, enabling manufacturers to meet stringent production standards efficiently.

When selecting a milling cutter, consider the type of material you will be machining. Different grades of carbide are tailored for specific applications, ensuring optimal results. For example, utilizing high-performance carbide cutters can drastically improve surface integrity and reduce tool wear, which is particularly important when working with challenging materials such as aluminum alloys.

Tip: Always assess the helix angle of your milling cutter, as it significantly influences cutting force and chip formation. A larger helix angle can reduce vibration while increasing axial force, leading to smoother operations. Additionally, regular maintenance and proper tooling selection will greatly enhance your machining efficiency and product quality, making it essential to stay updated on the latest innovations in the field.

Cobalt milling cutters have gained significant attention in the machining industry due to their superior performance when working with tough materials. They are primarily composed of high-speed steel with added cobalt, which enhances their hardness and heat-resistance properties. According to a report by the International Journal of Machine Tools and Manufacture, cobalt-enhanced tools can maintain their cutting edge even at temperatures exceeding 600°C, making them ideal for high-speed applications and the rigorous demands of aerospace and automotive sectors.

When machining materials such as stainless steel and Inconel, cobalt milling cutters demonstrate exceptional toughness and wear resistance, significantly reducing tool wear and improving overall productivity. The Machinery and Equipment Manufacturers Association highlights that using cobalt tools can increase tool life by 25-30% compared to standard high-speed steel cutters. Moreover, their ability to withstand thermal shock further alleviates the risk of catastrophic failure during the machining process, ensuring consistent performance and safety in manufacturing environments. As industries continue to push the boundaries of material capabilities, cobalt milling cutters emerge as a trusted solution for tackling the toughest machining challenges.

Specialized milling cutters play a crucial role in enhancing efficiency and precision in various machining applications. According to a recent market report by Grand View Research, the global milling tools market is projected to reach USD 7.45 billion by 2025, driven by the increasing demand for specialized tooling solutions. These cutters are designed to meet specific needs, providing advantages such as improved surface finishes and reduced cycle times. For instance, using a high-performance end mill can result in a 20% increase in productivity over standard tools when machining intricate geometries.

When selecting milling cutters for niche applications, it's vital to consider the material and desired finish. For challenging materials like titanium or high-temperature alloys, investing in coated carbide cutters can significantly enhance tool life and performance. Additionally, using the right coolant can help manage heat buildup, further prolonging cutter longevity.

Tip: Always assess the specific requirements of your machining project before choosing a milling cutter to ensure optimal performance and cost-effectiveness. Tailoring your choice based on factors such as workpiece material, desired tolerances, and finishing needs can lead to substantial savings and improved outcomes in production processes.