In today's competitive manufacturing landscape, selecting the appropriate cutter tool is paramount for enhancing productivity and maintaining quality standards. According to a report by the Freedonia Group, the global market for cutting tools is projected to exceed $35 billion by 2027, driven by the growing demand for precision-engineered components across various industries.

With advancements in materials and coating technologies, manufacturers face a plethora of options, making it crucial to choose a cutter tool that aligns with specific machining requirements. Understanding factors such as material compatibility, cutting speeds, and tool geometries can significantly impact operational efficiency and cost management. As the industry evolves, informed decision-making in cutter tool selection becomes not just beneficial, but essential for sustaining competitive advantages and meeting client expectations.

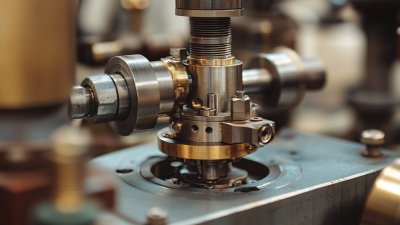

When selecting the right cutter tool

for manufacturing processes, it's essential to understand the various types available and their specific applications.

According to a report by Market Research Future, the global cutting tools market is anticipated to grow at a CAGR of over 6.5% from 2021 to 2027, driven by advancements in tool materials and coatings.

Cutter tools such as end mills, lathes, and drills serve distinct functions, each suited for different manufacturing needs.

For instance, end mills are ideal for producing complex shapes with high precision, while lathes are better suited for cylindrical workpieces.

Additionally, the choice of cutter tools also hinges on the materials being processed.

A study published in the Journal of Manufacturing Processes highlights that high-speed steel (HSS) tools are often employed for soft materials, while carbide tools show superior performance with harder materials due to their increased wear resistance.

The increasing demand for efficiency and productivity is prompting manufacturers to invest in specialized cutter tools that not only enhance machining quality but also reduce tool wear and maintenance costs.

Understanding the properties and applications of these tools can significantly impact the overall manufacturing workflow and end product quality.

When selecting the right cutter tool for your manufacturing needs, several key factors must be considered to ensure efficiency and effectiveness. First, the material of the cutter is crucial. According to a report from the Manufacturing Institute, tools made from high-speed steel (HSS) are ideal for general-purpose machining due to their durability and high-temperature resistance.

Conversely, carbide tools, while more expensive, offer superior hardness and wear resistance, making them suitable for high-speed cutting operations.

Tips: Always match the cutter tool material to the specific material being machined. For instance, when working with tough alloys, carbide tools can drastically reduce tool wear and enhance productivity.

Additionally, consider the geometry of the cutter tool, including its shape and edge design. Tools with sharp cutting edges and suitable geometries reduce cutting forces, which can significantly improve surface finish and reduce the chances of tool breakage. The International Journal of Advanced Manufacturing Technology indicates that appropriate geometry can increase tool life by up to 30%.

Tips: Conduct a thorough analysis of your machining processes and adjust the cutter geometry to optimize performance based on your specific production criteria, such as speed and precision.

When selecting the right cutter tool for your manufacturing needs, one crucial aspect to consider is material compatibility. Using the appropriate cutting tool tailored to specific materials directly influences cutting performance and overall efficiency in production. For instance, advancements in sustainable machining technologies have shown that the choice of cutting fluids is paramount; using eco-friendly alternatives can significantly reduce environmental impacts while enhancing tool longevity and performance.

In the context of emerging trends in sustainable building materials, the compatibility of cutter tools with these innovative materials—developed through advanced production technologies—is essential. As the industry shifts towards sustainable practices, manufacturers must evaluate how different cutter tools interact with materials like high-strength titanium alloys or new types of composites. The use of optimized machining parameters tailored to these materials, such as those derived from the Taguchi method, not only improves productivity but also aligns with the broader goal of reducing waste and increasing sustainability in manufacturing processes.

| Material Type | Recommended Cutter Tool | Cutting Speed (m/min) | Feed Rate (mm/rev) | Tool Life (hours) |

|---|---|---|---|---|

| Aluminum Alloy | High-Speed Steel (HSS) End Mill | 80 | 0.1 - 0.3 | 10 |

| Stainless Steel | Carbide Insert Tool | 50 | 0.05 - 0.1 | 8 |

| Mild Steel | Cobalt End Mill | 70 | 0.15 - 0.25 | 10 |

| Copper | Carbide Tipped Cutters | 60 | 0.2 - 0.4 | 9 |

| Titanium | Ceramic Tool | 40 | 0.03 - 0.1 | 6 |

In the manufacturing sector, selecting the right cutter tool involves not only understanding the material and application but also evaluating tool life and maintenance requirements. Studies show that tooling costs can account for up to 30% of a machining operation's total expenses. Therefore, choosing a tool with a longer lifespan can significantly reduce overall costs and downtime. For instance, carbide tools generally offer superior durability compared to high-speed steel, leading to longer tool life and increased efficiency in production processes.

When assessing tool life, it’s important to consider both the tool's wear rate and the frequency of required maintenance. A recent report highlighted that proper maintenance can extend tool life by as much as 50%, showcasing the importance of establishing a routine maintenance schedule.

**Tip:** Regularly inspect your cutter tools for signs of wear and tear to catch potential issues early.

**Tip:** Utilize tool condition monitoring systems to track performance variables and predict necessary maintenance, ensuring that you maximize the lifespan of your tools.

By implementing these strategies, manufacturers can not only enhance productivity but also optimize their costs effectively.

When selecting cutter tools for manufacturing, one of the key considerations is cost-effectiveness, which involves striking a balance between quality and budget. Manufacturers are increasingly leaning toward functional solutions that deliver optimal performance without breaking the bank. This means evaluating not just the initial purchase price of the tools but also their long-term value, durability, and efficiency in various applications. Investing in high-quality tools may seem costly upfront, but the longevity and productivity they offer can ultimately lead to substantial savings and better overall output.

Homeowners are similarly integrating functionality with aesthetics during renovations, opting for designs that not only look appealing but also serve practical purposes. Open-concept spaces, for instance, allow for flexibility and adaptability, making them ideal for modern living. This desire for a perfect blend of form and function is mirrored in the choice of tools, where users now prioritize those that enhance both performance and visual appeal. By understanding the unique demands of their projects, consumers can make informed decisions that respect their budgets while ensuring quality craftsmanship in their manufacturing endeavors.