In today's manufacturing landscape, the quest for efficiency and precision has never been more critical, particularly with the increasing demand for high-quality components across various industries. According to a recent market report from ResearchAndMarkets, the global PCD cutting tools market is projected to grow at a CAGR of 5.7% from 2021 to 2026, driven by advancements in automation and a growing preference for materials that improve wear resistance and extend tool life. PCD cutting tools, known for their superior hardness and thermal stability, are becoming indispensable for manufacturers seeking to enhance productivity and reduce operational costs. This blog aims to provide a comprehensive tutorial for beginners, focusing on the diverse applications, benefits, and comparative analysis of PCD cutting tools, to help you unleash their full potential in your machining processes.

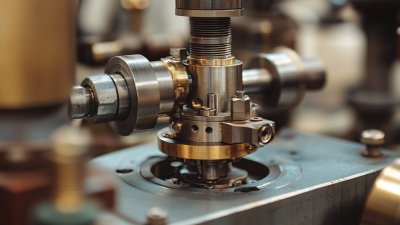

In recent years, the manufacturing sector has increasingly focused on enhancing efficiency and precision, and PCD (Polycrystalline Diamond) cutting tools have emerged as a vital solution. As manufacturers seek to reduce costs and improve productivity, PCD tools offer unique advantages, such as superior hardness, exceptional wear resistance, and the ability to maintain sharp cutting edges over extended periods. This makes them particularly valuable in high-volume production environments where precision and durability are paramount.

According to industry reports, the global metal cutting tools market is projected to grow from $86.24 billion in 2025 to $141.65 billion by 2032, with a compound annual growth rate (CAGR) of 7.3%. This growth is indicative of a shift towards advanced tooling solutions, as more manufacturers recognize the long-term cost benefits and enhanced performance attributed to PCD cutting tools. By investing in these tools, manufacturers not only ensure a higher quality of finished products but also significantly reduce downtime and maintenance costs, further driving manufacturing efficiency.

This bar chart illustrates the cutting efficiency percentage of various materials when using PCD cutting tools. The data indicates that Material C has the highest efficiency at 90%, showcasing the benefits of PCD tools in modern manufacturing processes.

Polycrystalline Diamond (PCD) tools have revolutionized various industries due to their exceptional material properties. PCD boasts nearly the same hardness as single crystal diamonds while offering superior anisotropy and comparable impact resistance to tungsten carbide. This combination makes PCD ideal for applications in oil and gas exploration, coal geological surveying, and high-performance cutting tools. According to recent market analysis, the global PCD market is segmented into solid and liquid forms, catering to diverse applications such as polyurethane elastomers and coatings.

For manufacturers looking to enhance efficiency, employing PCD cutting tools can lead to significant gains in productivity and cost-effectiveness. Tips for beginners include understanding the specific applications suited for solid versus liquid PCD; for instance, solid PCD is optimal for tooling due to its durability, while liquid PCD finds utility in coatings where flexibility is needed. Moreover, industry reports forecast steady growth in the PCD market, projecting a compound annual growth rate of approximately 5.5% through 2033, particularly driven by advancements in the construction and automotive sectors. Embracing these cutting-edge tools can ensure that companies remain competitive in a rapidly evolving marketplace.

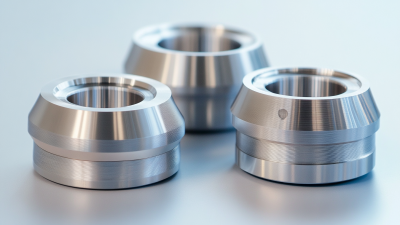

When it comes to cutting tools, polycrystalline diamond (PCD) tools are steadily gaining traction as a superior choice over traditional options. According to a report by Technavio, the global market for PCD tools is expected to grow by 6% annually, reflecting their increasing adoption driven by efficiency and cost-effectiveness. PCD tools offer significant longevity and wear resistance, often lasting up to 20 times longer than conventional carbide cutting tools, leading to reduced replacement frequency and downtime.

Performance metrics highlight the clear advantages of PCD tools in various applications. For instance, in machining aluminum and composite materials, PCD tools have demonstrated an impressive reduction in cycle times by 30-50% compared to standard carbide tools. Additionally, industry analysis from the American Machinist indicates that PCD tools can achieve a better surface finish and tighter tolerances, addressing quality concerns in high-precision industries. As manufacturers look to enhance productivity while minimizing costs, the shift toward PCD cutting tools presents a compelling case in the ongoing evolution of machining technology.

When it comes to machining processes, choosing the right cutting tools is pivotal for optimizing both productivity and cost-effectiveness. Polycrystalline Diamond (PCD) cutting tools have gained traction in various industries due to their superior performance and longevity. According to a recent study by Markets and Markets, the global market for PCD tools is expected to reach $3.1 billion by 2025, driven by the demand for high precision and efficiency in manufacturing operations. This growth underscores the trend toward preferring PCD cutting tools over traditional materials.

The financial efficiency of utilizing PCD cutting tools can be illustrated through a comprehensive cost-benefit analysis. Although the initial investment in PCD tools may be significantly higher—ranging from 30% to 50% more than carbide tools—the return on that investment can be substantial. For instance, PCD tools can last up to five times longer than their carbide counterparts, leading to decreased tool replacement costs and reduced downtime. Furthermore, studies have shown that PCD cutting tools can enhance cutting speed by up to 100%, ultimately resulting in increased production rates and lower per-unit costs. This data clearly demonstrates the long-term financial advantages of incorporating PCD tools into machining operations, making them a worthy consideration for manufacturers aiming to streamline processes and boost efficiency.

| Parameter | PCD Cutting Tools | Conventional Cutting Tools |

|---|---|---|

| Initial Cost (per tool) | $150 | $80 |

| Lifespan (hours) | 1000 | 300 |

| Production Rate (parts/hour) | 20 | 10 |

| Total Cost Over Lifetime | $750 | $640 |

| Profit from Production (per hour) | $600 | $300 |

| Net Profit Over Lifetime | $540,000 | $270,00 |

In the ever-evolving landscape of manufacturing, PCD (Polycrystalline Diamond) cutting tools are poised to play a pivotal role in enhancing efficiency. Future trends indicate a significant leap in technology with advanced coatings, enhanced tool geometries, and superior wear resistance. These innovations are designed to meet the increasing demands for precision and longevity in industrial applications. By adopting the latest PCD technologies, manufacturers can expect to reduce downtime and improve productivity.

Tip: Consider investing in PCD tools with nanostructured coatings that not only enhance hardness but also reduce friction. This could lead to longer tool life and improved surface finish, translating into lower production costs over time.

Moreover, automation and smart manufacturing are set to transform the usage of PCD tools. The integration of data analytics and IoT will allow for real-time monitoring of tool performance, enabling manufacturers to optimize tool usage and anticipate maintenance needs. This proactive approach ensures that production lines run smoothly and efficiently.

Tip: Implement a monitoring system that tracks the performance metrics of PCD tools. By analyzing this data, you can identify patterns and make informed decisions about tool maintenance and replacement, ultimately boosting operational efficiency.