In today’s competitive manufacturing landscape, the utilization of advanced tools and technologies plays a pivotal role in achieving precision and efficiency. One such essential tool is the milling cutter, which has become a cornerstone in various manufacturing processes. As industries continue to evolve, the significance of milling cutters extends beyond mere functionality; they are now integral to improving productivity, enhancing product quality, and driving innovation. Understanding their real-world applications can offer valuable insights into the sophisticated techniques that modern manufacturers employ to stay ahead in the market.

Milling cutters are versatile tools capable of shaping, carving, and cutting a wide range of materials, making them indispensable in sectors such as automotive, aerospace, and general manufacturing. From creating intricate designs to ensuring the exact specifications of components, the adaptability of milling cutters facilitates a plethora of manufacturing tasks. This blog explores the multifaceted roles of milling cutters in contemporary manufacturing, highlighting their essential contributions to efficiency, cost-effectiveness, and overall operational success. By examining these applications, we can appreciate not only the technological advancements but also the craftsmanship that defines modern manufacturing practices.

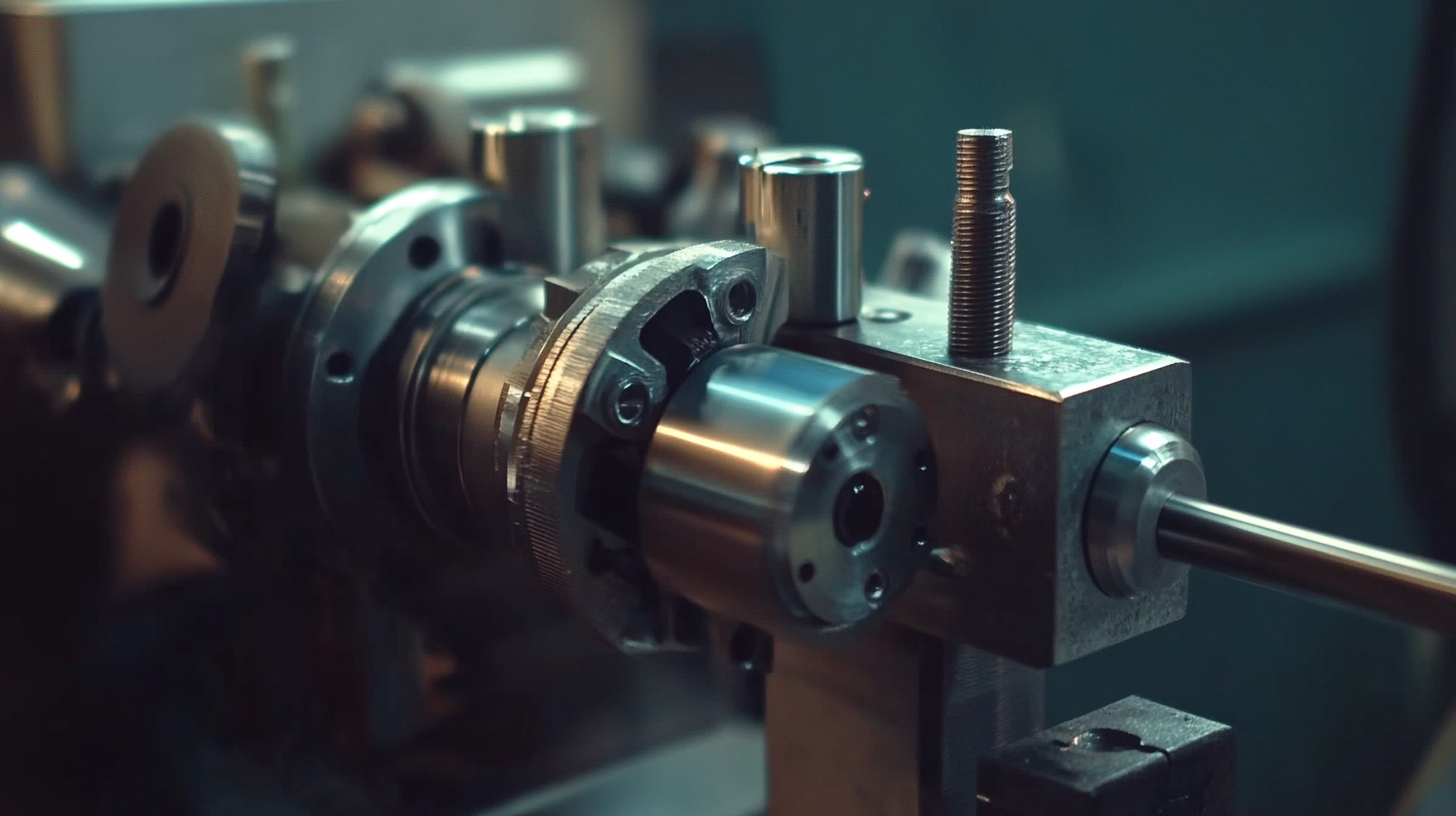

Milling cutters play a pivotal role in precision engineering, a field that demands extraordinary accuracy and consistency in manufacturing processes. These cutting tools are designed to remove material from a workpiece with impeccable precision, allowing for the creation of intricate shapes and features that are vital in various applications, from aerospace to medical devices. The versatility of milling cutters enables them to work with different materials, such as metals, plastics, and composites, making them indispensable in a world where tailored solutions are often required. In modern manufacturing, the application of milling cutters not only enhances productivity but also ensures high-quality output. CNC (Computer Numerical Control) machines, equipped with advanced milling cutters, operate with remarkable speed and repeatability, significantly reducing chances of human error. This technological advancement facilitates the production of components that adhere to tight tolerances, essential for maintaining the functionality and safety of complex systems. Consequently, the integration of precision-engineered milling cutters into industrial practices allows manufacturers to meet stringent regulatory standards while also driving innovation and competitive advantage. Ultimately, the significance of milling cutters in precision engineering goes beyond mere tool usage; they embody the marriage of technology and craftsmanship. As manufacturers seek to push the boundaries of what's possible, the evolution of milling cutter design and performance continues to fuel advancements within various industries. By providing the capability to produce exacting dimensions and flawless finishes, milling cutters remain at the forefront of modern manufacturing, ensuring quality and efficiency in an increasingly competitive landscape.

Innovations in milling cutter technology are revolutionizing modern manufacturing across various sectors, notably in aerospace and automotive industries. Recent achievements from institutions like Shanghai Jiao Tong University, which received a first-class award for their project on efficient cutting tool design and applications, exemplify the pivotal role of advanced milling cutters. These innovations not only enhance precision but also enable manufacturers to tackle increasingly complex materials, such as titanium alloys used in aircraft components, thereby improving operational efficiency and weight management.

The push for high-performance milling tools has also led to remarkable feats in precision engineering. For instance, the capability to engrave letters on a human hair demonstrates the extreme accuracy achievable with modern milling technology. This level of precision is essential in applications where every millimeter counts, particularly in industries where lightweight components are critical, as is evident in the aerospace sector. Furthermore, the ongoing trend towards electric vehicles necessitates the development of new cutting technologies to accommodate evolving materials and component designs.

In a rapidly changing manufacturing landscape, these technological advancements in milling cutters are not just about maintaining competitiveness; they are essential for fostering innovation and meeting the demands of modern production techniques. The focus on high efficiency and precision in milling cutter development illustrates a broader commitment to driving forward the frontiers of manufacturing capability.

Milling cutters have become indispensable tools in various industries, offering competitive advantages through enhanced precision and efficiency. Key sectors such as aerospace, automotive, and electronics rely heavily on milling cutters to meet the rigorous demands of modern manufacturing. The aerospace industry, in particular, has seen significant advancements thanks to innovative milling tools that set new standards for machining tough materials. These tools enable manufacturers to create intricate designs while maintaining high levels of accuracy, which is crucial for safety and performance.

In the automotive industry, milling cutters play a vital role in the production process, allowing for the mass production of complex components with minimal waste. As manufacturers strive for greater automation and precision, the demand for advanced milling machines continues to rise. The global milling machine market is projected to grow steadily, reflecting the increased focus on efficiency and productivity. Additionally, the integration of CNC (Computer Numerical Control) technology has revolutionized the way milling operations are conducted, facilitating high-speed manufacturing that meets contemporary requirements.

Furthermore, the adoption of milling cutters extends beyond traditional manufacturing sectors. Industries such as electronics are leveraging these tools for precision machining of delicate components, which is essential for creating reliable and high-performance devices. As manufacturing processes evolve, the importance of milling cutters in driving innovation and maintaining competitive advantages across multiple sectors cannot be overstated.

In the fast-evolving landscape of modern manufacturing, customization and versatility in milling processes are proving to be game changers. As industries demand more tailored solutions to meet specific operational needs, the role of sophisticated milling cutters has never been more critical. Recent advancements in precision cutting tools are reshaping how manufacturers approach their machining challenges, particularly in sectors like aerospace and medical, where precision is paramount.

Custom CNC tool manufacturing is at the forefront of this revolution, honing in on the unique requirements of each application. For instance, the ability to mill PTO shafts using modified cutting tools not only increases quality but also enhances the versatility of machining operations. Data indicates that manufacturers that adopt customized tooling solutions can achieve up to 30% increased efficiency in their production lines, demonstrating a direct correlation between tool customization and operational performance.

Moreover, the integration of advanced milling cutters allows for intricate designs that traditional methods often can't achieve. With the rise in demand for on-site milling solutions, portable chainsaw mills have garnered popularity among woodworkers and DIY enthusiasts, offering an unparalleled level of convenience. Reports project that the demand for such versatile milling tools will continue to grow, as manufacturers increasingly prioritize adaptable and efficient production methods to stay competitive in a dynamic market.

The advancement of milling cutter applications in modern manufacturing is being significantly driven by emerging trends in technology and efficiency. As industries increasingly prioritize precision and automation, the CNC cutting machines market is projected to reach an impressive USD 11,671.4 billion by 2032. This surge is indicative of the growing demand for intricate manufacturing processes that can accommodate complex materials. The incorporation of Computer Numerical Control (CNC) technology enhances the capability of milling cutters, allowing them to produce high-quality components with improved accuracy and reduced waste.

In addition to CNC technology, the integration of Artificial Intelligence (AI) and Machine Learning (ML) into manufacturing processes is another trend shaping the future of milling applications. These technologies enable real-time data analysis and process optimization, which are essential for improving manufacturing efficiency under the Industry 4.0 paradigm. This transition is particularly relevant in industries like aerospace and automotive, where the production of fiber-reinforced composites is becoming commonplace due to their lightweight yet robust properties. As manufacturers seek innovation and cost-effective solutions, milling cutters equipped with AI and digital twin technologies are poised to revolutionize the production landscape.

Furthermore, the increasing emphasis on resource-efficient processes is driving the demand for advanced manufacturing techniques such as Electrical Discharge Machines (EDM). As industries aim to utilize complex materials with heightened resource efficiency, EDM technology will play a pivotal role in supporting these goals, enhancing manufacturing productivity while minimizing environmental impact. As these trends continue to evolve, milling cutters will remain at the forefront of transformation in manufacturing, essential for meeting the intricate demands of the future.