The landscape of global manufacturing is continuously evolving, driven by advancements in technology and the increasing demand for precision engineering. Among the pivotal innovations that have emerged is the Graphite Milling Machine, a specialized tool that has transformed the machining of graphite materials. As industries strive for greater efficiency and accuracy, understanding the developments in this area becomes crucial. The evolution of graphite milling machines not only reflects changes in manufacturing processes but also highlights the growing importance of these machines in various applications, from aerospace to electronics.

In this blog, we will delve into the significant insights and trends shaping the future of graphite milling machines by 2025. We will explore the technological advancements that have streamlined production workflows, increased operational capabilities, and enhanced the performance of these machines. Furthermore, we will examine the role of graphite milling machines in addressing the challenges faced by manufacturers today, providing a comprehensive overview of how these tools are set to influence the global manufacturing landscape in the coming years.

The global graphite industry has witnessed significant growth over the past few years, driven primarily by the soaring demand for electric vehicle batteries and renewable energy technologies. According to a report by Global Market Insights, the graphite market is expected to surpass $20 billion by 2025, expanding at a CAGR of approximately 4.5%. This booming market is prompting advancements in milling technology, particularly in the manufacture of graphite milling machines. The evolution of graphite milling machines is directly influenced by the industry's demands for precision and efficiency. Modern milling machines are now equipped with advanced features such as automated tool changes and enhanced cooling systems, allowing for improved processing of graphite materials. As highlighted by a recent study from Technavio, the demand for high-purity graphite used in anode production is expected to increase significantly, necessitating the development of milling technologies that can provide finer and more consistent particle sizes while minimizing contamination. Furthermore, the rise in production capacities among major graphite producers is pushing for more robust milling solutions. Companies that previously relied on conventional milling techniques are now investing in CNC-based milling machines that offer better control and versatility. The shift towards automation and smart manufacturing in the graphite sector is reshaping the landscape of milling technology, ensuring that manufacturers can meet the stringent quality standards required by end-use industries such as lithium-ion battery production and steelmaking.

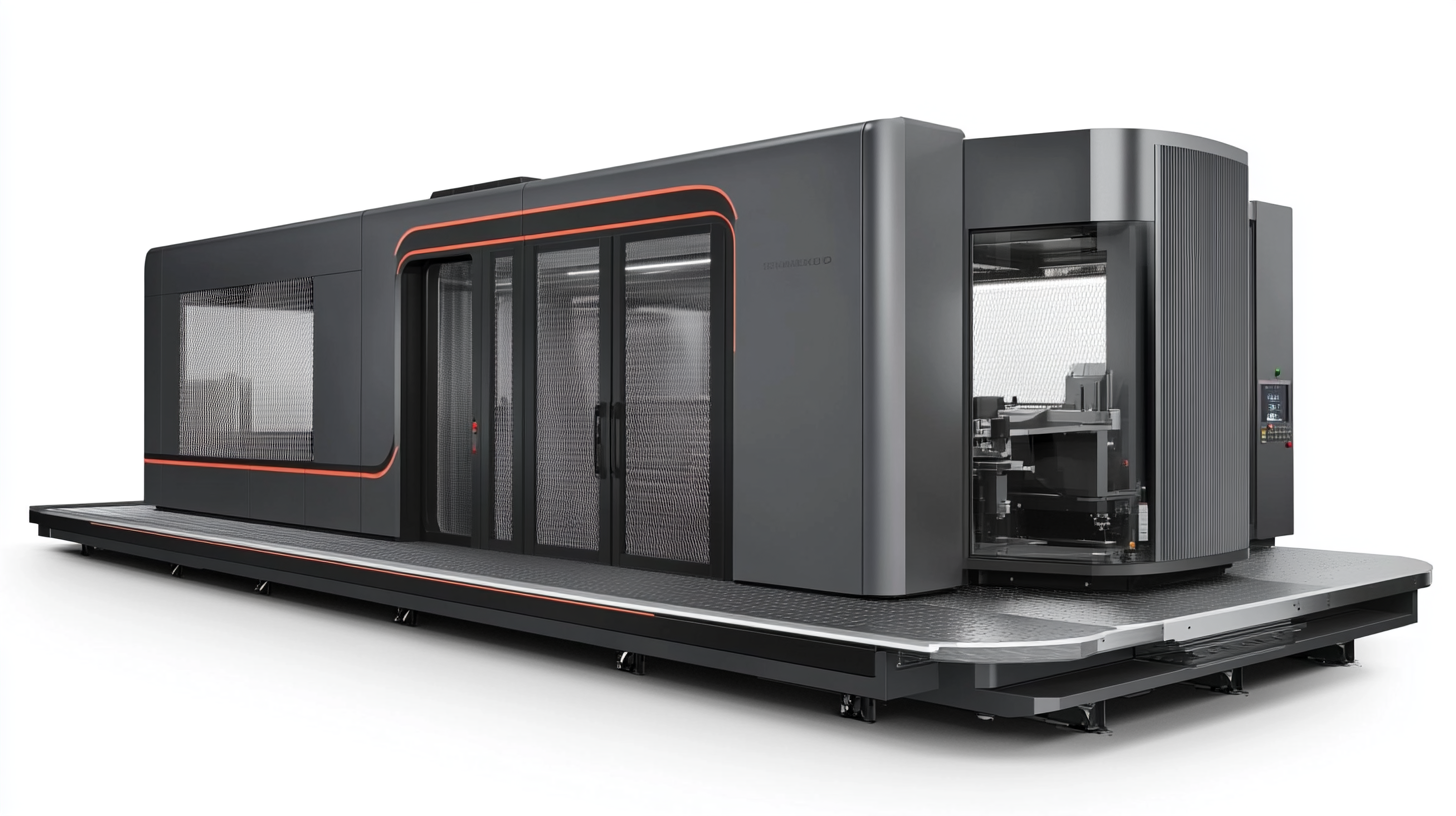

The landscape of graphite milling machines is undergoing a revolutionary transformation driven by cutting-edge technological advancements that are set to reshape global manufacturing by 2025. As the demand for high-quality graphite in applications such as lithium-ion batteries continues to surge, manufacturers are focusing on improving milling techniques to produce nano-sized graphite particles. This evolution is not just about enhancing efficiency; it's also about responding to the pressing safety challenges associated with graphite processing.

Innovative milling technologies are emerging that prioritize both productivity and safety. Advanced dust collection systems and automated controls are now integral to modern machines, helping to mitigate the risks of dust exposure that can arise during the milling process. Manufacturers are embracing smart technologies, such as AI and IoT, to optimize milling operations, ensuring that machines maintain precise settings and monitor safety metrics in real time. This data-driven approach not only improves the quality of the final product but also adheres to stringent health and safety regulations in battery manufacturing environments.

As we approach 2025, the focus on sustainable practices will further influence the evolution of graphite milling machines. Energy-efficient designs and environmentally friendly processes will become the norm, reflecting a broader commitment to minimizing the ecological footprint of manufacturing operations. These advancements are not only crucial for meeting industry demands but also align with the growing emphasis on responsible sourcing and sustainability within the supply chain. The future of graphite milling is bright, characterized by innovation, safety, and environmental stewardship.

The global demand for precision and efficiency in graphite milling is driving significant advancements in manufacturing technologies. As we approach 2025, the CNC machine market is projected to grow substantially, estimated to expand from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a compound annual growth rate (CAGR) of 9.9%. This growth highlights the industry's shift towards more automated and precise manufacturing processes, essential for enhancing productivity and minimizing waste in graphite milling operations.

In parallel, the Pressureless Sintered Silicon Carbide Plus Graphite market is also on a commendable trajectory. It is anticipated to grow from USD 200 million in 2024, indicating a robust interest in advanced materials that enhance the performance of milling machines. The increasing integration of these materials is greatly influenced by the rising need for high precision in complex component manufacturing, which is essential for industries like aerospace and automotive.

Moreover, the rise of the metalworking fluids market further emphasizes the industry's focus on refining operational efficiency. As technological advancements continue to emerge, and sustainability becomes a priority, the demand for innovative metalworking fluids is expected to increase. This trend showcases the broader commitment within the manufacturing sector to leverage technology and improve processes, ultimately meeting the high standards of precision and efficiency that modern production entails.

The evolution of graphite milling machines in global manufacturing is increasingly intertwined with sustainability practices. As industries strive to reduce their environmental footprint, innovations in graphite milling technology have emerged to meet the demands of stricter regulatory pressures. Manufacturers are now focusing on minimizing waste and energy consumption in their milling processes. Advanced machining techniques, such as high-efficiency milling and closed-loop systems, are being employed to enhance resource use and recycle materials.

In addition to technological advancements, companies are also adapting to regulatory changes that emphasize sustainability. New policies often mandate reductions in emissions and require the use of eco-friendly materials. This regulatory landscape is pushing manufacturers to not only comply with standards but also to adopt best practices that can lead to long-term sustainability. For instance, integrating renewable energy sources into the milling operations and utilizing biodegradable lubricants are steps currently being explored.

The commitment to sustainability in graphite milling goes beyond compliance; it reflects a broader industry trend towards social responsibility. By investing in greener technologies and adhering to regulations, manufacturers are not only contributing to environmental conservation but are also enhancing their competitive edge in the market. This alignment of sustainability with innovation is shaping the future of graphite milling machines, paving the way for a more eco-conscious manufacturing landscape.

The global manufacturing landscape is rapidly changing, particularly with the advancements in graphite milling machines that are becoming essential in various industrial applications. As we approach 2025, the competition among leading manufacturers is intensifying, driving innovations that enhance precision and efficiency. These machines, integral for producing complex components in sectors such as aerospace and automotive, are adapting to meet the rising demands for lightweight and durable materials, primarily graphite.

Manufacturers are focusing on cutting-edge technologies, such as CNC (Computer Numerical Control) systems, which improve the accuracy of machining processes while minimizing waste. Enhanced software solutions and real-time monitoring capabilities are increasingly adopted, allowing manufacturers to analyze production metrics and optimize workflows. This evolution is not just about performance—it's also about sustainability, as new machining processes are designed to reduce energy consumption and material waste, aligning with global trends toward eco-friendly practices.

The competitive analysis of key players reveals a diverse range of strategies, from investing in research and development to forming strategic partnerships. As these leading manufacturers continue to push the boundaries of what graphite milling machines can achieve, the industry is poised for significant transformation. The insights gleaned from market trends indicate a promising future where efficiency, precision, and sustainability converge, redefining the role of graphite milling machines in global manufacturing.