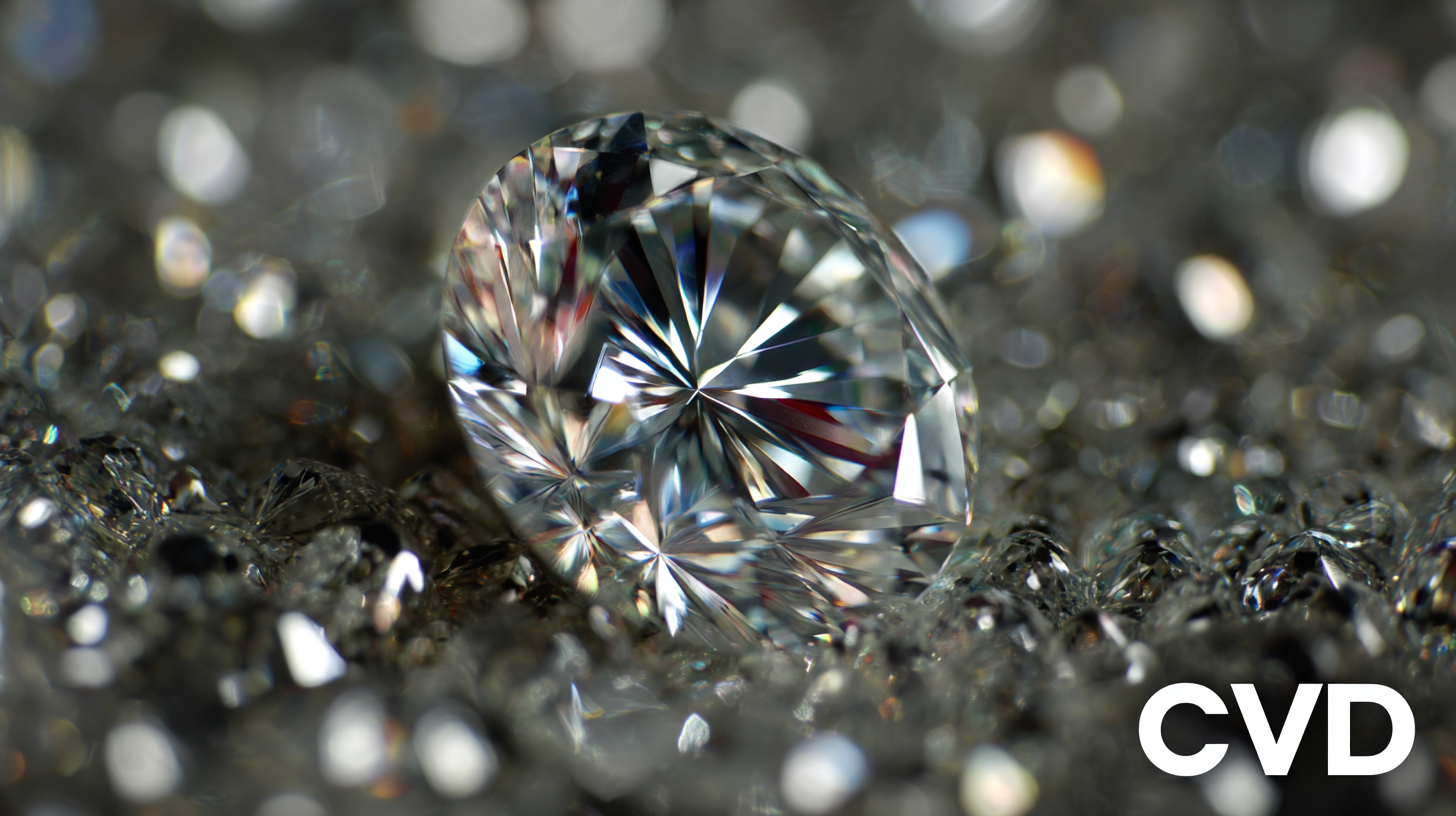

The CVD diamond process has emerged as a revolutionary method for synthesizing high-quality diamonds, with applications spanning from cutting tools to electronics and luxury goods. According to a report by Grand View Research, the global synthetic diamond market is expected to reach $29.2 billion by 2025, fueled by the increasing demand for CVD diamonds due to their superior properties and lower production costs compared to natural diamonds. As industries seek innovative approaches to optimize the CVD diamond process, it becomes imperative to explore various comparison methodologies that highlight the efficiency, cost-effectiveness, and sustainability of different synthesis techniques. By analyzing these innovative strategies, stakeholders can enhance production techniques, improve product quality, and ultimately drive the growth of the synthetic diamond market.

The diamond industry is on the brink of transformation, particularly in the realm of Chemical Vapor Deposition (CVD) diamond production. Forecasts suggest that the lab-grown diamonds market will witness explosive growth, with a projected size of approximately USD 97.85 billion by 2034, up from USD 29.73 billion in 2025. This rapid expansion emphasizes the importance of innovative techniques and emerging technologies that are redefining CVD diamond processes.

Among these advancements, robotic diamond cutting and polishing systems are leading the charge, offering precision and efficiency previously unattainable by human craftsmen. The introduction of such robotic technologies can significantly reduce production times, thus enhancing productivity in an already disrupted market dominated by lab-grown diamonds. Meanwhile, significant breakthroughs in synthetic diamond technology are emerging from countries like China, which are attracting attention from major U.S. tech entities due to their revolutionary potential in the industry.

The synthetic diamond market is also expected to grow steadily, with a compound annual growth rate (CAGR) of 5.1%, reaching USD 25.9 billion by 2024. This underscores the increasing competitive landscape where companies must adapt to consumer preferences for sustainable and ethically produced diamonds. These innovative approaches will be pivotal in shaping the future of CVD diamond production, positioning the industry for a sustainable and profitable tomorrow.

| Technology | Description | Advantages | Challenges | Future Trends |

|---|---|---|---|---|

| Plasma CVD | Utilizes plasma to enhance the deposition rate of diamond. | Higher growth rates, improved film quality. | Equipment cost, complexity of process. | Integration with other materials, cost reduction. |

| Microwave CVD | Employs microwave energy to maintain high temperature and pressure. | Uniform film deposition, low contamination. | High energy consumption, equipment complexity. | Energy efficiency improvements, scaling up production. |

| Hot Filament CVD | Uses heated filaments to produce diamond films. | Lower costs, simple setup. | Lower quality films, slower growth rates. | Improvement in growth rates, enhancements in film quality. |

| Chemical Vapor Deposition (CVD) with 3D Printing | Combines CVD with additive manufacturing techniques. | Customization of diamond structures, rapid prototyping. | Technical challenges in process integration. | Advancements in material properties, broader application scopes. |

| Nano-Material Integration | Incorporating nanomaterials into CVD processes. | Enhanced mechanical properties, better thermal conductivity. | Complexity in material interaction and uniformity. | Development of hybrid materials, new application areas. |

The landscape of CVD diamond manufacturing is rapidly evolving, particularly with a growing emphasis on sustainable practices. By 2025, the integration of eco-friendly processes will not only enhance the quality of diamonds produced but also mitigate environmental impacts. Innovative methods like utilizing renewable energy sources and recycling water in the diamond growth process will become standard practices, paving the way for a more responsible industry.

As personalization gains traction in fine jewelry, consumers are increasingly seeking unique pieces that reflect their individual style and values. Sustainable CVD diamonds, with their customizable nature, provide the perfect solution, allowing manufacturers to create one-of-a-kind designs while adhering to environmentally conscious principles. This alignment of craftsmanship and sustainability not only enriches the consumer's experience but also sets a new benchmark for luxury in the jewelry sector. The commitment to ethical sourcing and production will ultimately reshape the market, attracting a discerning clientele that values both beauty and responsibility.

The realm of Chemical Vapor Deposition (CVD) for diamond synthesis is evolving rapidly, particularly with innovative techniques aimed at enhancing efficiency. One promising approach is the Floating Catalyst Chemical Vapor Deposition (FC-CVD) process, which has successfully accelerated the synthesis of carbon nanotubes. This technique exemplifies how new methods can streamline production while maintaining high-quality output, paving the way for similar advancements in CVD diamond growth.

Recent explorations into low-temperature methods, such as low-temperature hot-filament CVD (LT-HFCVD), are also showcasing the potential for improved performance in diamond-coated tools. Operating at temperatures between 500–600 °C, this technique opens doors to utilizing cemented carbide substrates more effectively. By bridging theoretical research with practical application, innovations like these highlight a trend toward maximizing the efficiency of creation and application in CVD processes, ultimately leading to enhanced performance in industries dependent on precision machining and cutting tools.

The year 2025 is set to be a pivotal moment for the CVD diamond industry, driven by significant market trends influencing its applications and development. Recent gatherings, such as the successful Carbontech 2024 event in Shanghai, highlighted the rapid advancements in diamond semiconductor technologies, with industry leaders discussing the potential for practical applications by 2025-2030. Notably, various companies are exploring the use of CVD diamond in heat sink materials, aiming to revolutionize thermal management solutions crucial for enhancing the performance and reliability of electronic devices.

As the demand for high-performance materials surges, the competitive landscape for CVD diamond production continues to evolve. The market is witnessing a blend of traditional techniques and innovative approaches, paving the way for improved product functionalities. High thermal conductivity composites are emerging as key players in this sector, addressing the urgent need for efficient heat dissipation in electronics. This trend is supported by ongoing technical advancements and a growing number of enterprises investing in CVD diamond technologies, setting the stage for substantial growth in the coming years.

The world of Chemical Vapor Deposition (CVD) diamond technology is rapidly evolving, and collaboration between researchers and industry leaders is becoming a critical element in driving advancements. By pooling resources and expertise, stakeholders can tackle complex challenges more effectively. Joint research initiatives often lead to innovative solutions that push the boundaries of what is possible, allowing for the development of higher-quality diamonds with improved properties for various applications, ranging from electronics to jewelry.

Furthermore, partnerships foster a culture of knowledge sharing that accelerates the pace of innovation. When academic researchers work alongside industry professionals, they bridge the gap between theoretical knowledge and practical applications. This synergy can lead to breakthrough discoveries, such as novel techniques that enhance the efficiency of the diamond growth process while reducing costs. As the CVD diamond industry continues to mature, it is clear that collaboration will be a fundamental pillar supporting its growth and success. By prioritizing joint efforts, we can unlock the full potential of CVD diamonds and transform them into even more indispensable materials for the future.