The global market for CNC machines has witnessed significant growth, driven by advancements in technology and the increasing demand for precision manufacturing across various industries. According to a recent report by MarketsandMarkets, the CNC machines market is projected to reach $117.93 billion by 2027, with graphite CNC machines playing a crucial role due to their ability to enhance productivity and efficiency in manufacturing processes.

However, buyers often encounter common challenges when selecting quality graphite CNC machines, such as identifying reliable manufacturers and understanding the technical specifications required for their specific applications. In this blog, we will explore effective strategies for overcoming these challenges and guiding global buyers in choosing the best graphite CNC machines that not only meet their needs but also contribute to their overall operational success.

CNC machining has revolutionized the manufacturing sector, yet global buyers still encounter a range of challenges that can hinder efficiency and productivity. One of the most prominent issues is the complexity of sourcing high-quality graphite CNC machines. Given the vast options available, understanding which machines deliver the best performance for specific applications is crucial. Buyers often struggle with inadequate technical support and varying levels of machine precision, which can lead to costly downtime and compromised product quality.

To navigate these challenges, it's essential for buyers to conduct thorough research before making a purchase. Engage with industry forums and resources to gain insights into the performance and reliability of different graphite CNC machines. Additionally, consider establishing relationships with reputable suppliers who offer comprehensive customer support and training. This can significantly reduce the learning curve associated with new equipment.

Another common issue is the variability in machine compatibility with existing manufacturing setups. Buyers should assess their current processes and machinery to ensure the new equipment integrates smoothly. Investing time in planning for a smooth transition can save significant resources in the long run. Remember to seek advice from experts in machinery setup for tailored guidance that addresses your specific needs.

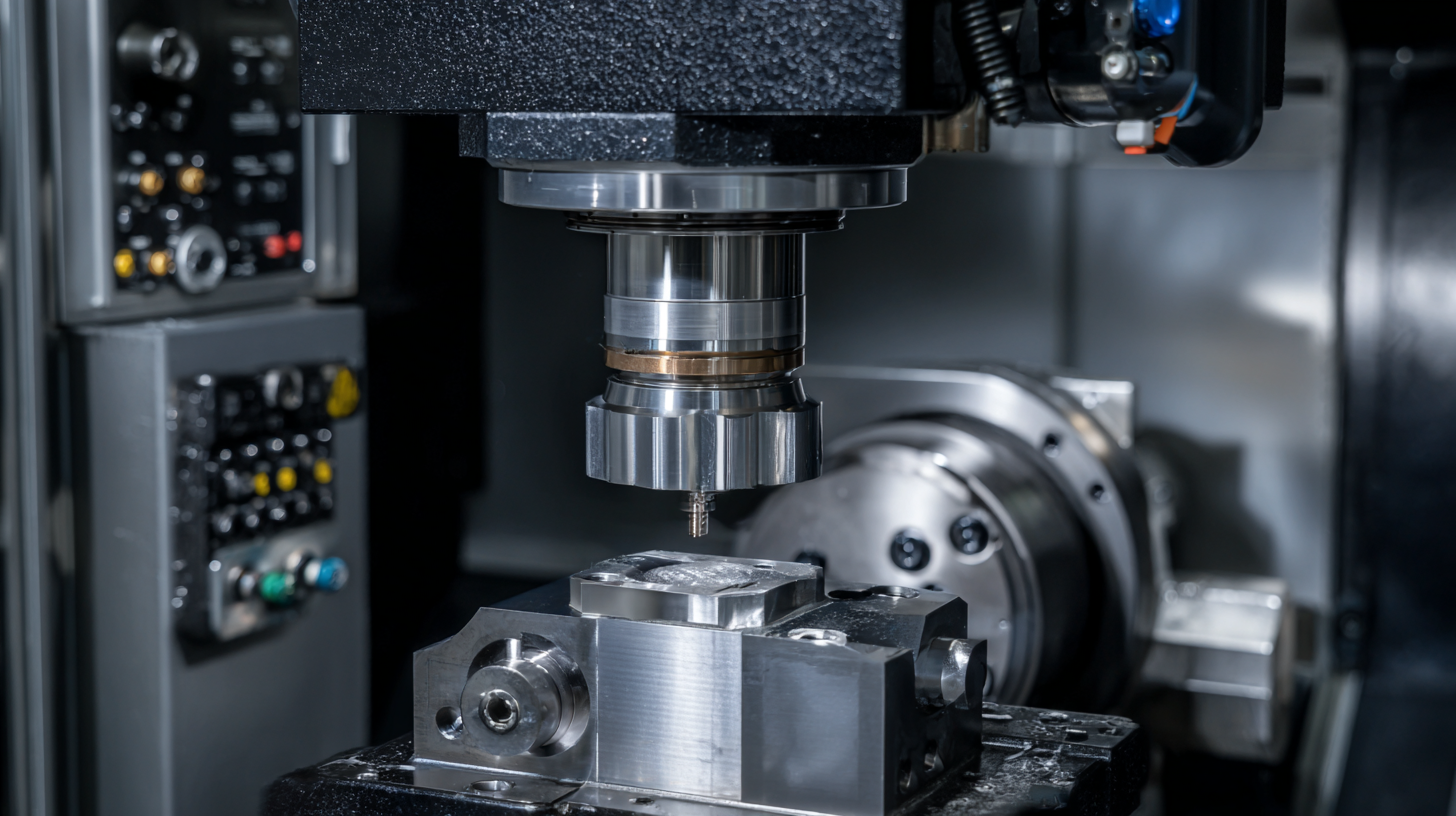

In the fast-evolving landscape of manufacturing, advanced graphite CNC machines have emerged as vital tools for overcoming common industry hurdles. These machines are specifically designed to handle the unique properties of graphite, allowing for precise machining and reducing waste. One of the major challenges in working with graphite is its brittleness, which can lead to chipping and inconsistent finishes. Innovative solutions such as adaptive machining strategies and specialized tooling have been developed, ensuring smoother operations and enhanced durability of the finished products.

Furthermore, the integration of advanced software solutions has revolutionized the programming and operation of graphite CNC machines. With features like real-time monitoring and predictive maintenance, operators can preemptively address potential issues, thereby minimizing downtime and maximizing productivity. These technological advancements not only improve efficiency but also allow manufacturers to push the boundaries of design and innovation, making it possible to create complex geometries that were previously unattainable. By embracing these cutting-edge technologies, global buyers can navigate the challenges of graphite machining with confidence and unlock new opportunities for growth and excellence in their operations.

Graphite CNC machines have become integral in various industries, showcasing their versatility and effectiveness through real-world applications. In sectors like aerospace and automotive, these machines excel in producing intricate components that are lightweight yet durable. For instance, a notable success story involves a leading aerospace manufacturer that utilized graphite CNC machining to create complex molds for turbine blades, improving production efficiency and reducing material waste.

Another compelling application can be seen in the electronics industry, where precision is paramount. By integrating graphite CNC technology, companies have achieved remarkable advancements in producing high-quality heat sinks for lithium-ion batteries. This development is crucial, as it directly contributes to enhancing battery health diagnostics and prognostics, ultimately leading to better-performing electric vehicles. The ability to manufacture precisely engineered components not only accelerates product development but also addresses challenges in battery technology by ensuring optimal thermal management. As industries continue to evolve, the demand for such innovative solutions will only grow, affirming the value of graphite CNC machines across various sectors.

Graphite CNC machines have become essential tools in precision manufacturing, thanks to their ability to handle the unique properties of graphite. Graphite is a strong yet brittle material, which presents challenges in machining processes. However, the integration of high-speed milling technologies significantly enhances the efficiency and precision of graphite machining. By adopting advanced CNC machines, manufacturers can streamline their workflows and improve overall productivity.

Tips for successful graphite machining include using the right tools to minimize wear, as graphite's abrasiveness can quickly degrade equipment. It’s advisable to opt for solid carbide end mills specifically designed for graphite to achieve smoother finishes and extended tool life. Additionally, maintaining optimal spindle speeds and feed rates can help reduce overheating, which is crucial for preserving the integrity of machined parts.

Investing in modern graphite CNC machines allows manufacturers to overcome common challenges associated with mold and die machining. These advanced machines provide the capability to produce intricate designs with high accuracy, making them a preferred choice for industries that require exceptional detail and surface quality. By leveraging the benefits of these CNC machines, businesses can effectively meet the increasing demands for precision in their manufacturing processes.

The evolution of graphite CNC technology is poised to transform manufacturing processes across the globe. As industries increasingly adopt automation, the demand for sophisticated techniques to process graphite has surged. Graphite CNC machines are not only enhancing precision but also improving efficiency, making them indispensable in sectors like aerospace, electronics, and automotive manufacturing. With innovative features such as advanced tool path algorithms and real-time monitoring systems, these machines minimize waste and maximize productivity, setting the stage for a new era in precision engineering.

Furthermore, future trends in graphite CNC technology indicate a shift toward sustainability and eco-friendliness. As manufacturers look to reduce their carbon footprint, there is an increasing emphasis on machines that integrate green technologies. Hybrid approaches combining traditional and additive manufacturing processes are expected to gain traction, allowing for greater flexibility and material conservation. As global buyers navigate these advancements, they are not just investing in machinery but are also embracing a future where graphite CNC technology plays a pivotal role in supporting sustainable practices and driving competitive advantages in the manufacturing landscape.