The Steering Cylinder is a vital component in many vehicles. It plays a crucial role in ensuring smooth and responsive steering. This hydraulic device converts hydraulic pressure into mechanical force, allowing for precise control. Understanding how a steering cylinder works can help in vehicle maintenance and safety.

When turning the steering wheel, the steering cylinder activates. It pushes or pulls the steering linkages, effectively changing the direction of the wheels. This action is essential for maneuvering a vehicle, especially in tight spaces. Yet, not every driver fully grasps its importance.

Neglecting the steering cylinder can lead to issues. For instance, leaks or damage can compromise steering control. Regular inspection is key to keeping it in top shape. Thus, awareness about the steering cylinder is important for all drivers. It might not be the most glamorous part of a vehicle, but it is certainly one of the most important.

A steering cylinder is a vital component in various vehicles, particularly those using hydraulic systems. Its primary purpose is to assist in steering by converting hydraulic pressure into mechanical force. This allows the driver to maneuver the vehicle effectively. It plays a key role in ensuring smooth and responsive steering, enhancing driving safety and comfort.

The steering cylinder consists of several parts, including a piston and seals. Hydraulic fluid enters the cylinder, pushing the piston and creating motion. When the piston moves, it turns the steering mechanism. This process can be complex, but it is essential for accurate steering. Regular maintenance of the steering cylinder is crucial. Wear and tear can lead to leaks or malfunctions.

Tip: Check your vehicle's hydraulic fluid levels regularly. Low levels can compromise steering performance.

Another aspect to consider is the alignment of the steering cylinder. Misalignment can lead to uneven wear on tires and reduced steering response. Drivers should be aware of unusual noises or vibrations when turning.

Tip: If you notice any signs of trouble, consult a professional. Early diagnosis can save time and money.

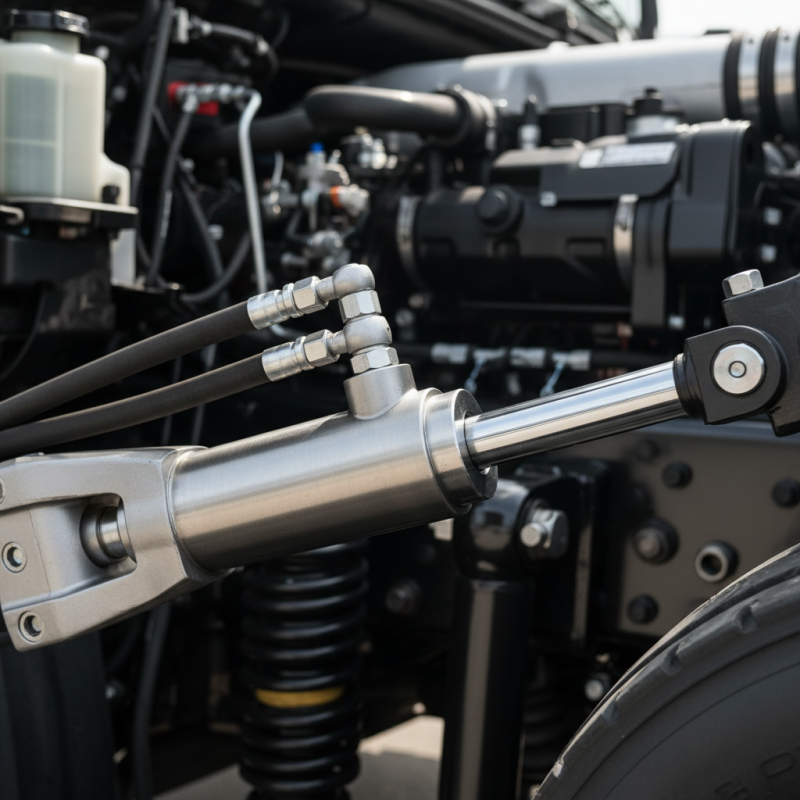

A steering cylinder is a crucial component in hydraulic steering systems. It converts hydraulic pressure into linear movement, allowing the vehicle to turn effectively. Understanding its components can help clarify how it functions.

One important part is the piston. The piston moves inside the cylinder when hydraulic fluid enters. This movement translates pressure into steering action. Then, there is the rod connected to the piston. It extends or retracts, steering the wheels of the vehicle. The seals within the cylinder prevent fluid leaks, maintaining pressure. They are vital yet often overlooked in discussions.

Another key component is the hydraulic fluid. Its quality impacts performance. Contaminated fluid can lead to failures. Maintenance is necessary but sometimes neglected. A well-functioning steering cylinder enhances vehicle control. However, it may not work optimally without regular checks.

| Component | Function | Material | Typical Dimensions |

|---|---|---|---|

| Cylinder Barrel | Houses the piston and contains hydraulic fluid | Steel or Aluminum | Length: 12-24 in, Diameter: 2-4 in |

| Piston | Creates hydraulic pressure to assist in steering | Aluminum or Cast Iron | Diameter: 1.5-3 in |

| Seals | Prevent leakage of hydraulic fluid | Rubber or Synthetic Materials | Varies by application |

| Ports | Allow hydraulic fluid in and out of the cylinder | Steel or Aluminum | Standardized sizes |

| Rod | Transmits force from the piston to the steering mechanism | Steel | Diameter: 1-2 in, Length: Varies |

The steering cylinder plays a crucial role in vehicle steering systems. It converts hydraulic energy into linear motion. This action helps steer the vehicle safely and effectively. When the driver turns the steering wheel, hydraulic fluid moves through the steering system. This fluid travels to the steering cylinder, initiating movement.

Inside the cylinder, a piston shifts back and forth. This movement alters the angle of the wheels. With precise engineering, the steering cylinder offers responsiveness. However, wear and tear can diminish performance over time. Regular maintenance is essential to ensure it functions properly.

The connection between the steering wheel and the wheels is vital. When the steering cylinder malfunctions, it can lead to handling issues. Drivers may experience delayed responses or difficulty steering. Addressing these problems requires careful inspection and sometimes replacement. It's a reminder that even small components are vital for safety.

Steering cylinders play a crucial role in the sophisticated steering systems of various vehicles. In trucks, they provide precise control, allowing drivers to navigate tight corners easily. When a driver turns the steering wheel, the cylinder helps translate that motion into movement. It creates a hydraulic force that adjusts the angle of the wheels.

In construction vehicles, steering cylinders enhance maneuverability. These machines often work in confined spaces. The steering system allows operators to pivot sharp corners and navigate rough terrain without compromising stability. However, there are challenges. Maintenance issues in hydraulic systems can lead to reduced responsiveness. Regular checks can help prevent such problems.

Similarly, agricultural vehicles depend on steering cylinders for efficient operation. Tractors utilize these components to turn smoothly in fields. The technology adjusts the steering dynamically. Yet, if these systems fail, it can lead to significant downtime. Ensuring that all parts are in good shape is essential, but not always straightforward. It requires diligence from operators and mechanics alike.

Steering cylinders play a crucial role in vehicle control. Regular maintenance can enhance their lifespan significantly. Start by checking for leaks; fluid puddles can indicate a problem. Inspect hoses and connections for any signs of wear. Keeping these parts in good condition can prevent larger issues.

Cleaning the steering cylinder regularly is essential. Dirt and debris can accumulate, leading to corrosion. Use a soft cloth and appropriate cleaning agents. Ensure that all seals are intact to avoid contamination. Pay attention to unusual noises while steering. These could signal that something isn’t functioning properly.

Lastly, monitor the fluid levels consistently. Low fluid can lead to steering difficulties. Refill promptly with the recommended type. Neglecting these simple tasks may lead to costly repairs. Remember, preventive care is always better than reactive measures. Taking time to inspect your steering system can save you frustration down the road.