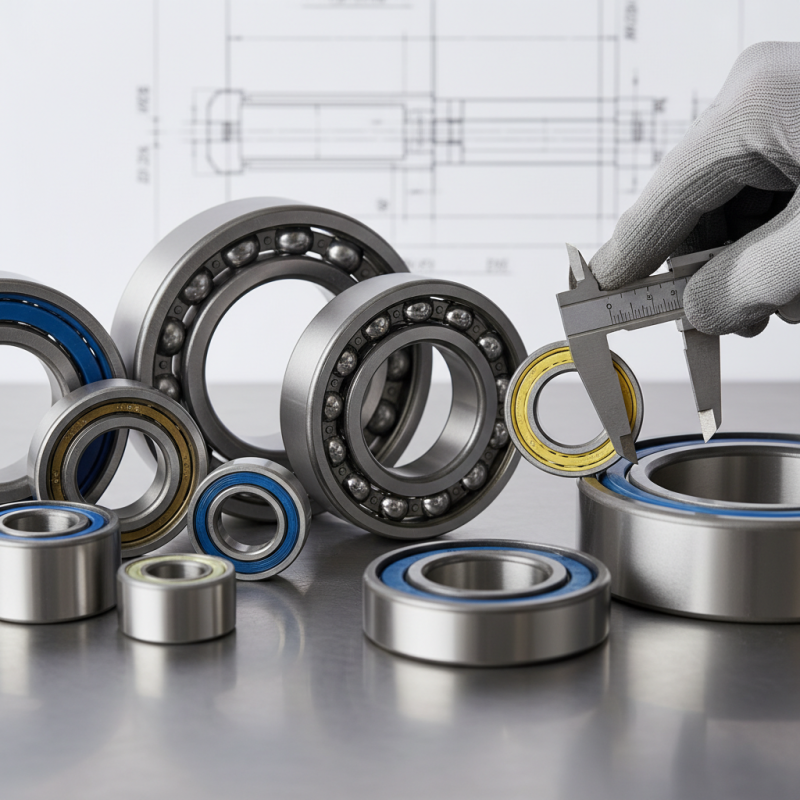

Choosing the right Ball Bearing is crucial for various applications, from automotive to industrial machinery. According to industry reports, ball bearings are foundational components that reduce friction and improve efficiency. The global ball bearing market is projected to reach over $20 billion by 2026, highlighting their significance.

When selecting a ball bearing, one must consider several factors including load capacity, speed rating, and material. Different applications demand different qualities in bearings. However, many fail to evaluate these characteristics thoroughly. Understanding your specific needs can prevent costly mistakes that may arise from selecting the wrong type.

Despite their importance, choosing the right ball bearing is often overlooked. A common misstep is assuming all bearings are interchangeable. This leads to unexpected failures and maintenance issues. It’s essential to reflect on your choices and ensure the best fit for your application. In an industry where precision counts, every detail matters.

When selecting the right ball bearing, different types must be understood. Ball bearings come in various designs, each with unique characteristics. For example, deep groove ball bearings are versatile and suitable for high-speed applications. They account for approximately 50% of the market share in bearing types, according to the latest industry analysis.

Another type worth noting is angular contact bearings. They are ideal for high-speed and high-load applications. However, their complexity means they can be costly and challenging to install. In contrast, self-aligning ball bearings offer ease of installation and are preferable in situations where shaft misalignment may occur. It is estimated that self-aligning bearings have a 15% penetration in certain industrial sectors.

Choosing the wrong type can lead to performance issues. An inappropriate bearing may result in premature failure or excessive vibrations. This situation can be critical in high-performance machinery. Research indicates that 30% of bearing failures stem from incorrect selection. Ensuring the right bearing type is essential for optimal performance in mechanical systems. Each application’s specific demands should dictate the choice of bearing.

When choosing ball bearings, load ratings and speed capability are critical factors. Load ratings indicate how much weight the bearing can support. This is usually specified as dynamic and static load ratings. Understanding the application is vital. If the load exceeds these ratings, it can cause premature failure. This reflects the importance of thorough calculations before selection.

Speed capability also plays a significant role. Each bearing has a maximum limit for speed; exceeding this can lead to overheating. The materials used in the bearing will influence this capability. For example, steel bearings typically handle higher speeds than plastic ones. It’s essential to explore the consequences of poor material choice. Users may overlook how these factors interact, leading to failures in operation.

Remember, not all applications are the same. Factors such as temperature, environment, and lubrication can affect performance. A mismatch in selections can create costly downtime. Careful consideration of these elements can prevent mistakes. Always double-check calculations and consider real-world scenarios.

When selecting ball bearings, choosing the right material is crucial. Three common options are stainless steel, ceramic, and plastic. Each material has its unique benefits, and considerations for their use are important.

Stainless steel bearings are durable and resistant to corrosion. They are suitable for heavy loads. However, they can rust in humid environments. Ceramic bearings are lightweight and have a lower friction coefficient. This can enhance speed and reduce wear. Yet, they can be more brittle than their metal counterparts. Plastic bearings are non-corrosive and lightweight. They are useful for applications involving moisture. But they may not always withstand heavy loads.

Tips for choosing the right material include assessing the environment. Is it wet or dry? Consider the temperature ranges too. Evaluate the load requirements; this can significantly impact performance. Remember to think about the application's speed. Some materials perform better at different speeds. Reflect on whether the benefits outweigh potential drawbacks in your context. Choosing wisely can prevent future issues. Consider your specific needs carefully before making a decision.

| Material | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Stainless Steel | Corrosion resistant, durable, cost-effective | Heavy, lower precision than ceramics | Industrial machinery, automotive applications |

| Ceramic | Lightweight, high precision, excellent wear resistance | Expensive, brittle | Aerospace, high-performance motors |

| Plastic | Lightweight, corrosion resistant, cost-effective | Lower load capacity, wear rate can be high | Household appliances, light machinery |

Lubrication plays a critical role in the performance of ball bearings. Proper lubrication minimizes friction between moving parts, which enhances efficiency. Without adequate lubrication, bearings can overheat and wear out quickly. Most industry reports suggest that up to 40% of bearing failures stem from inadequate lubrication. This statistic highlights the necessity for regular maintenance.

There are various lubrication methods available. Grease is often recommended for its ability to stay in place. However, oil lubrication can provide better cooling and faster heat dissipation. The choice depends on the application's specific needs. Consider an application that operates at high speeds; oil lubrication may prevent thermal overload. On the other hand, a slower application might benefit more from grease's stability.

It's essential to apply the right amount of lubricant. Too much lubricant can lead to aeration, while too little can increase wear rates. Data shows that incorrect lubrication can reduce bearing life by as much as 50%. Striking the right balance requires careful consideration. Monitor and adjust lubrication practices regularly to maintain optimal performance.

When choosing ball bearings, manufacturer specifications play a crucial role. Look closely at material types. Steel and ceramic are common choices. Each offers different benefits. Stainless steel is resistant to corrosion. However, it can be heavier. Ceramic bearings are lighter but typically more expensive. Understanding these materials helps determine which suits your needs.

Pay attention to tolerances. High precision can be vital, especially in machinery. Check whether the tolerances meet your specific application. Sometimes, manufacturers provide a range of tolerances. This can lead to confusion. Not every application needs high precision. For casual projects, standard tolerances may suffice.

Vibration and noise levels are also indicators of quality. A bearing that operates smoothly will generate less noise. Manufacturers may provide data on vibration ratings. This information is crucial if you're concerned about operational impacts. Remember, not all specifications tell the whole story. Some might lack detail. Be prepared to ask questions. Failing to request clarification can lead to poor choices. Keep these factors in mind when analyzing specifications.

This chart illustrates the analysis of different ball bearing specifications based on their load capacity, rotational speed, and material type. The data shows the importance of these factors in ensuring quality assurance in bearing selection.