In the world of precision machining, the role of the "Turning Tool" is irreplaceable. According to a recent report by the Precision Manufacturing Institute, optimizing turning tools can enhance production efficiency by up to 30%. This insight underscores the importance of mastering advanced techniques in tool selection and usage.

Industry experts emphasize the need for precision in every aspect. John Smith, a leading authority in machining technology, states, "Effective use of turning tools can dramatically improve quality and reduce waste." His perspective highlights a crucial point: attention to detail in tool application is vital for success.

However, the industry faces challenges. Many machinists often overlook the nuances of tool geometry and material selection. These oversights can lead to suboptimal results. Embracing a deeper understanding of turning tool techniques requires effort but can yield significant rewards. Constant reflection on these practices is essential for continuous improvement in machining processes.

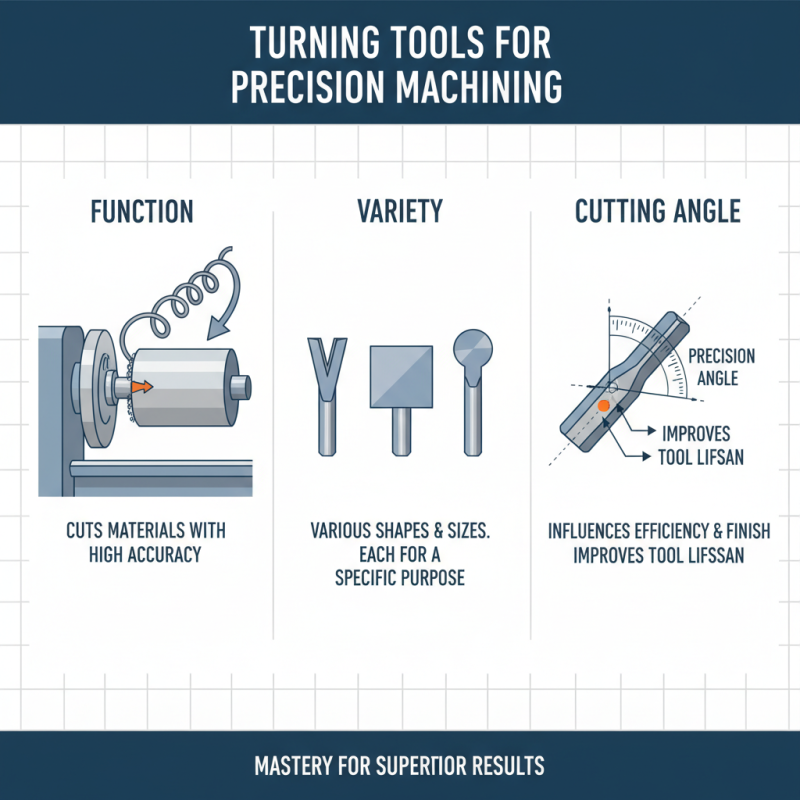

Understanding turning tools is vital for precision machining. These tools cut materials with high accuracy. They come in various shapes and sizes, each serving a specific purpose. A turning tool typically features a sharp blade mounted at a precise angle. This angle significantly influences the cutting edge's efficiency. Selecting the right angle can enhance both the finish and the lifespan of the tool.

Many machinists overlook the importance of tool material. Common materials include high-speed steel, carbide, and ceramic. Each type has its strengths and weaknesses in different applications. For instance, carbide tools are incredibly durable but can be brittle. Machinists must evaluate their needs carefully. Poor tool choice can lead to subpar results, wasted materials, and increased costs.

Proper setup is crucial for using turning tools effectively. Tool position and secure mounting affect the precision of the machining process. Even a slight misalignment can result in a mismatch or poor finish. Maintaining the right cutting speed is also essential. Too fast, and the tool may wear prematurely; too slow, and it might not cut effectively. Therefore, attention to detail is critical in achieving optimal performance in precision machining.

High-performance turning tools play a crucial role in precision machining. These tools are designed to enhance accuracy and efficiency. One of their key features is cutting-edge geometry. A well-designed tool can minimize friction and improve chip removal. This helps maintain a consistent cutting edge even during prolonged use.

Another important aspect is the material composition. High-speed steel and carbide are common choices. They offer durability and resist wear. However, not all tool materials are perfect for every application. Choosing the wrong material can lead to poor performance and increased costs. It's essential to evaluate specific needs before selecting a tool.

Coating technology also contributes to accuracy. Coatings can reduce tool wear and improve surface finish. However, over-reliance on coatings may lead to neglecting other critical factors, such as tool setup. Practicing proper alignment and adjustments is just as vital. Tools may continue to perform inadequately if technicians overlook these foundational steps.

Precision in turning processes is essential for achieving high-quality machined parts. Optimizing cutting parameters can lead to improved efficiency and product quality. Key parameters include cutting speed, feed rate, and depth of cut. Each of these elements must be carefully selected to match the material being worked on.

Tips: Always test different settings on scrap material before full production. This can help identify the best parameters without wasting valuable resources. Variability in materials means that a one-size-fits-all approach won't work.

Finding the right balance is crucial. If the cutting speed is too high, it can lead to tool wear and damage. Conversely, too low a speed can cause excessive heat and reduced surface finish. Regular monitoring is also needed. Over time, tool performance changes. Adjustments to cutting parameters may be necessary as tools wear down.

Tips: Maintain a log of cutting conditions and results. This can aid in identifying trends and improving machining processes over time. Experimentation is valuable, but so is learning from past experiences. Precision machining demands attention to detail and an adaptable mindset.

Maintaining turning tools is crucial for achieving precision in machining. Clean tools perform better. Regular cleaning removes debris. This simple practice prevents wear and tear, extending tool life. Observing the tool's condition is essential. Check for chips, dull edges, or any signs of damage. Address issues promptly to avoid larger problems.

Proper storage can also enhance longevity. Tools should be stored in a dry, clean place. A cluttered workspace can lead to accidents and damage. Consider using protective cases or holders. These measures keep tools organized and safe from unnecessary impact.

Unexpected tool failures can occur. A sudden chip or break can disrupt production. This highlights the need for routine inspections. Set up a regular schedule. Forgotten tools may need additional care. Reflecting on past experiences can improve practices. Identifying what went wrong helps develop better habits.

The evolution of turning tool technology has dramatically impacted precision machining. Innovations now allow for tighter tolerances and improved surface finishes. One notable advancement is the use of ceramic and carbide materials that withstand higher temperatures and pressures. These materials enhance wear resistance and prolong tool life.

Another area of focus is the development of geometric designs. Unique cutting edge configurations reduce vibration and improve chip removal. This results in sharper, cleaner cuts. Nevertheless, the complexities of these designs require careful consideration. There’s a learning curve; not all operators master them quickly.

Additionally, smart machining techniques are being integrated into new tools. IoT-enabled turning tools monitor performance in real-time. This technology offers data-driven adjustments to enhance precision. However, reliance on technology poses risks. Not every operator is savvy with these advancements. Training is crucial to bridge this gap.